|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Apr 07, 2012 7:41 pm Post subject: Next generation wig-wag controller for LED lamps Posted: Sat Apr 07, 2012 7:41 pm Post subject: Next generation wig-wag controller for LED lamps |

|

|

At 01:20 PM 4/7/2012, you wrote:

| Quote: | --> AeroElectric-List message posted by: "gregmchugh" <gregmchugh(at)aol.com>

Bob,

Thanks for the info.

What is the limiting factor on power to the LED's?

I am planning to use the Teledyne LED lights that use 45 watts, so

about 4 amps at 12 volts for each light. What changes would be

needed to up the power capability by a factor of two. Different parts?

Different packaging? Different connector? Heatsinks? |

Heatsinks. Just because a device is RATED at xx

amps, doesn't mean that it will carry that current

waving around in breeze . . . unless it's a strong

breeze and maybe down around -40 or so. The parts

as shown are good for over 10A if the FETs are

thoughtfully accommodated with respect to getting

rid of their heat.

Actually, these fets might be okay at 5A with little

or no heatsinking . . . didn't bother to run the numbers.

But in any case, upsizing for the larger lamps is no big

deal.

| Quote: | What is the frequency of the wig-wag function and how is that set

by the components? |

The 1M/1uF network sets flash rate. That combination

with the 4093's I had in the bin gave about 340 mS

in one state and 450 mS in the others. One of the

characteristics of the cmos-gate astable is that

the hysteresis band is not centered between Vcc/Vdd,

hence the peg-leg gait of the flash pattern.

Of course, this wouldn't hurt the serviceability of

the device . . . in fact, folks would know who was

inbound from many miles out by the pattern of your

wig-wag.

The 'fix' would be to add a resistor and diode in

parallel with the 1M and adjust for better symmetry

-OR- change the oscillator to a 555 timer -OR- add

a divide by two flip-flop and double the frequency

of the oscillator.

The design goal was minimum parts count but with some

additional 'silicon herbs and spices' . . . the flavor

of the dish can be improved.

| Quote: | I am a software engineer so I know enough

about hardware design to be dangerous, but I am in the process

of learning more. |

Good for you! We all gotta start somewhere. My career

got officially launched in the basement of an uncle who

was big wig engineer for local power company. He taught

me the early motions of soldering things together . . .

with an iron that was the size of a billy club and took

20 minutes to warm up!

Hmmm . . . if you can herd the bytes around in a

microcontroller, there are some $1 devices from PIC that

would take care of your flash timer and push-pull outputs

to logic level gates on power fets. Of course, other

inputs could be used to control OFF/WW/ON functionality.

If you're interested in getting your feet wet in

etched circuit board layout, check out the free

CAD package from expresspcb.com

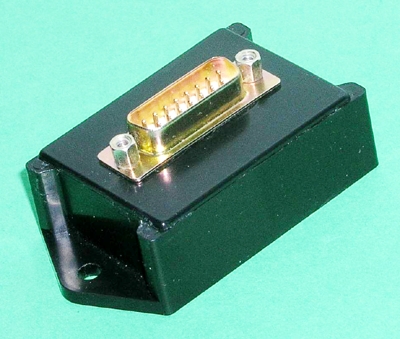

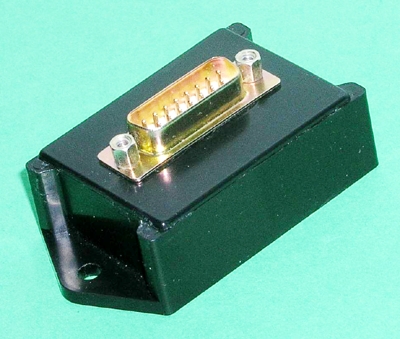

It might even be that the end-product can be fitted

into this stock enclosure

[img]cid:.0[/img]

There's a gazillion ways to do this. Let's pick one

that gets your juices going . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

109.43 KB |

| Viewed: |

6012 Time(s) |

|

|

|

| Back to top |

|

|

gregmchugh

Joined: 03 Apr 2012

Posts: 42

|

Posted: Sun Apr 08, 2012 9:47 am Post subject: Re: Next generation wig-wag controller for LED lamps Posted: Sun Apr 08, 2012 9:47 am Post subject: Re: Next generation wig-wag controller for LED lamps |

|

|

Bob,

Thanks for the follow-up info.

I do like the idea of going with a micro to allow programmable

functions with a standard module/connector design.

What is the source for the d-sub enclosure you suggested?

How much current can be handled by a single pin on the connector?

Greg McHugh

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Apr 08, 2012 2:12 pm Post subject: Next generation wig-wag controller for LED lamps Posted: Sun Apr 08, 2012 2:12 pm Post subject: Next generation wig-wag controller for LED lamps |

|

|

At 12:47 PM 4/8/2012, you wrote:

--> AeroElectric-List message posted by: "gregmchugh" <gregmchugh(at)aol.com>

Bob,

Thanks for the follow-up info.

I do like the idea of going with a micro to allow programmable

functions with a standard module/connector design.

What is the source for the d-sub enclosure you suggested?

got a bucket full of them . . .

How much current can be handled by a single pin on the connector?

5A but I'd parallel up two pins for each power

path . . . there are plenty of extras. I qualified

this process on a military targets program about

15 years ago.

http://tinyurl.com/7h9h76r

for this power distribution controller

http://tinyurl.com/8x5rssq

for this target

http://tinyurl.com/6myc494

Works good, lasts a long time.

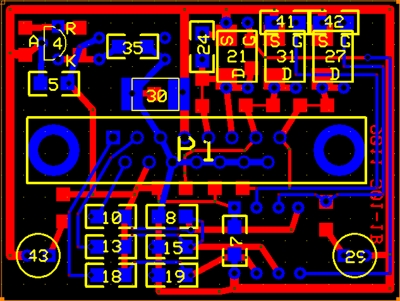

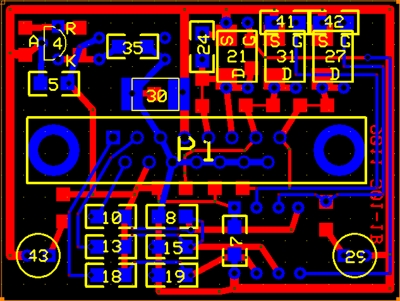

First gate to pass is to select logic level

FETs with sufficient current rating and make

sure you can get rid of the heat in this

2.8 x 1.4 footprint.

[img]cid:.0[/img]

Here's the schematic for this particular layout.

http://tinyurl.com/7m56z8o

Depending on what parts are put on, which are

left off, what the values are and what software

is in the uC, you can do a lot of different things

with it . . . and probably the next generation

wig wag.

You game to herd byes in a PIC RISC?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

130.09 KB |

| Viewed: |

5984 Time(s) |

|

|

|

| Back to top |

|

|

gregmchugh

Joined: 03 Apr 2012

Posts: 42

|

Posted: Mon Apr 09, 2012 8:21 am Post subject: Re: Next generation wig-wag controller for LED lamps Posted: Mon Apr 09, 2012 8:21 am Post subject: Re: Next generation wig-wag controller for LED lamps |

|

|

Bob,

I probably should have changed the Subject line on this but I decided to leave it alone to continue

the thread we had started. It is getting away from the LED wig-wag topic...

I have thought about this a little and I think it would be worthwhile to consider the option of a general purpose

programmable module and use the LED wig-wag as a simple example application. I see three useful

characteristics for this module:

1. Functionality set in software

2. Some capability to configure the I/O circuits for each application

3. A standard module package and connector such as the one you showed using an enclosed case with d-sub connector

To be useful for a wide audience there needs to be simple learning curve for developing the software

functionality and I/O configuration. I agree that the use of a PIC micro would be the way to go based on

their ready availability, good price per performance, and availability of development tools.

In order to make it attractive for general use I would propose the following:

Software Development - The learning curve for using the standard PIC software development tools

is pretty steep for a novice and I would expect many would shy away from that learning curve. There

are some third party development tools designed to ease the learning curve but at a price of $150 and up

they are not targeted at the novice hobbyist. An attractive option is the line of PICAXE micros targeted

at the education market and easily applied to the types of applications being considered here (I don't

think we are looking at applications that require high performance embedded processing). You can

get started with PICAXE development for $25 to $50 depending on which processor and which

downloading cable you use. The PICAXE development environment is free and easy to use for the

novice with the capability to simulate the micro operation without connection to a micro. The use

of a version of BASIC designed for embedded applications makes it easy to program but there

is an execution speed hit due to the use of a code interpreter in the PICAXE micro instead of using a compiler

to generate machine code for a plain PIC. Again, I don't see this execution speed penalty as a major issue for

most applications. As you gain experience you could make a switch to standard PIC micros and

use C or assembly language. The group behind PICAXE (Revolution Education in Britain) gets funds from

selling the PICAXE versions of the PIC micro (preloaded with the program loader and interpreter) and

development boards/kits. Here is a link to the free software development environment:

http://www.picaxe.com/Software/PICAXE/PICAXE-Programming-Editor

You can find more PICAXE info at (including lots of examples and tutorials):

http://www.picaxe.com/

and there are three U.S. distributers:

http://www.sparkfun.com/categories/125

http://www.robotshop.com/search/search.aspx?locale=en_us&keywords=picaxe

http://www.phanderson.com/picaxe/

I/O Configuration - In parallel with a need for easy software development I see a need for easy configuration

of I/O interfaces to the devices outside the module. There a plenty of examples and tutorials for interfacing

the PICAXE to all types of devices and here are some examples of general purpose modules that allow

I/O configuration (usually through the provision of a prototyping area on the module):

From VX-Aviation, the Proton-225 board based on a PIC micro with a prototyping area and a package

using standard d-sub 25 pin connectors and housing which is compatible with the other products they provide. You can download a pdf description here:

http://www.vx-aviation.com/docs.html

From PICAXE there are several standard development boards that include the provision for varying levels of I/O configuration:

http://www.picaxe.com/Hardware/Project-Boards/PICAXE-08-Proto-Board/

http://www.picaxe.com/Hardware/Project-Boards/PICAXE-14-Project-Board/

http://www.picaxe.com/Hardware/Project-Boards/PICAXE-18-Project-Board/

I don't know enough about hardware design to know if the use of these types of boards or even just a prototyping board

from Radio Shack are robust enough to handle the environment of mounting in an experimental aircraft but based on the

VX-Aviation module it would seem they may be up to the job...

Anyway, this note is getting a little long so I will end it here. I would appreciate feedback from anyone who is interested

in something along these lines in order to see if my thoughts on this make any sense to anyone beside me. I am only

interested as an end user of the module and have no real interest in designing / producing any type of hardware boards.

I can handle setting up the I/O circuits on a pre-made board but I don't have much interest in board development even

though I know it is something that is not that hard to learn. Just a matter of only so many things that you can do, even

when you are retired from a "real" job. I have read and studied the AeroElectric Connection book and have a draft

design for the electrical system on the Sonex Xenos motor glider that I am building. But as I pointed out in a previous note,

like most software engineers, I know just enough about hardware design to be dangerous...

Greg McHugh

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Apr 10, 2012 3:38 pm Post subject: Next generation wig-wag controller for LED lamps Posted: Tue Apr 10, 2012 3:38 pm Post subject: Next generation wig-wag controller for LED lamps |

|

|

At 11:57 AM 4/9/2012, you wrote:

| Quote: |

To that goal, I'd like to suggest using an Arduino.

|

This is a highly capable device but a bit of an

overkill for things like wig-wag flashers, voltage

monitors, etc.

The challenge is to exploit the scope of

projects that can be implemented in a user

friendly package of the smallest practical

size, cost and parts count. An already stuffed

Arduino board has no aviation friendly i/o

or even an enclosure for $30. I would expect

the wig-wag flasher to be drop-in ready for

use on an airplane and have total bill of

materials under $20 or so.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

fvfdums

Joined: 13 Dec 2019

Posts: 1

|

Posted: Sun Dec 15, 2019 7:48 pm Post subject: Re: Next generation wig-wag controller for LED lamps Posted: Sun Dec 15, 2019 7:48 pm Post subject: Re: Next generation wig-wag controller for LED lamps |

|

|

oh,it is a good idea.Good ideas are just for everyone to share.

--------------------------------------------------------------------

My stepper motor website:skysmotor.com - Machinery Design ? - ? Stepper Moter Development

"Necessity is the mother of invention." - Author unknown.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Dec 16, 2019 8:16 am Post subject: Next generation wig-wag controller for LED lamps Posted: Mon Dec 16, 2019 8:16 am Post subject: Next generation wig-wag controller for LED lamps |

|

|

At 09:48 PM 12/15/2019, you wrote:

| Quote: | --> AeroElectric-List message posted by: "fvfdums" <kakaxiu9(at)gmail.com>

oh,it is a good idea.Good ideas are just for everyone to share.

--------------------------------------------------------------------

My stepper motor website:skysmotor.com ( https://www.skysmotor.com/) - Machinery Design ? - ? Stepper Moter Development

"Necessity is the mother of invention." - Author unknown. |

INTERLOPER . . . IGNORE

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|