|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

johngoodman

Joined: 18 Sep 2006

Posts: 530

Location: GA

|

Posted: Tue May 18, 2010 5:25 pm Post subject: Need a frank answer Posted: Tue May 18, 2010 5:25 pm Post subject: Need a frank answer |

|

|

Installing my panel the other day, I discovered that the maximum sized hole you can cut in the sub-panel for the radio rack (according to page 41-4) is insufficient for four typical radio rack components. Yet, I have seen many panels on display that have been able to accomplish this feat.

Before I go back to the drawing board, I need an honest answer from somebody on how this can be accomplished - without compromising the structural integrity required on 41-4.

Here's the situation: PS 9000X, 430W, SL-40, GTX-330. They all stick through the sub-panel (the PS doesn't, but try putting a connector on the back with a turn radius). The real issue is the bottom inch or so of the sub-panel has to be cut for the GTX-330 to fit, unless you move the entire stack to the absolute top of the panel, which brings up other unwanted issues.

Cutting that bottom inch is unthinkable, but it's obvious some of you have found a way around this. What is it? I had a friend suggest a "C" channel all the way across the bottom of the sub-panel flange, where only the tiny flange is still intact. Assuming this is good engineering, has it been done?

I realize some folks will want to hedge on this, but I'd appreciate any "hear-say" that you might have heard....

Respectfully,

John

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

#40572 Phase One complete in 2011 |

|

| Back to top |

|

|

rv10builder(at)verizon.ne

Guest

|

Posted: Tue May 18, 2010 6:41 pm Post subject: Need a frank answer Posted: Tue May 18, 2010 6:41 pm Post subject: Need a frank answer |

|

|

Tim did this, check out his site and the panel section great pictures to

show how he did it.

Pascal

--------------------------------------------------

From: "johngoodman" <johngoodman(at)earthlink.net>

Sent: Tuesday, May 18, 2010 6:25 PM

To: <rv10-list(at)matronics.com>

Subject: Need a frank answer

| Quote: |

Installing my panel the other day, I discovered that the maximum sized

hole you can cut in the sub-panel for the radio rack (according to page

41-4) is insufficient for four typical radio rack components. Yet, I have

seen many panels on display that have been able to accomplish this feat.

Before I go back to the drawing board, I need an honest answer from

somebody on how this can be accomplished - without compromising the

structural integrity required on 41-4.

Here's the situation: PS 9000X, 430W, SL-40, GTX-330. They all stick

through the sub-panel (the PS doesn't, but try putting a connector on the

back with a turn radius). The real issue is the bottom inch or so of the

sub-panel has to be cut for the GTX-330 to fit, unless you move the entire

stack to the absolute top of the panel, which brings up other unwanted

issues.

Cutting that bottom inch is unthinkable, but it's obvious some of you have

found a way around this. What is it? I had a friend suggest a "C" channel

all the way across the bottom of the sub-panel flange, where only the tiny

flange is still intact. Assuming this is good engineering, has it been

done?

I realize some folks will want to hedge on this, but I'd appreciate any

"hear-say" that you might have heard....

Respectfully,

John

--------

#40572 QB. Working on Cowling & Panel

N711JG reserved

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=298130#298130

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

n223rv(at)wolflakeairport

Guest

|

Posted: Tue May 18, 2010 6:56 pm Post subject: Need a frank answer Posted: Tue May 18, 2010 6:56 pm Post subject: Need a frank answer |

|

|

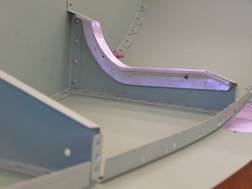

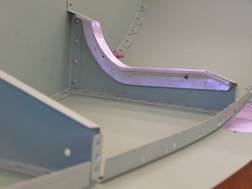

I put on a .020 doubler angle on the front, and an .063 extruded AL

piece on the back all the way across the width of the sub panel. The

front angle ties to the vertical bulkheads, the rear butts next to them.

No real engineering analysis done, but it worked in my buddies -10 for

300+ hours and I'm doing the same. This really stiffens up this area.

YMMV

-Mike

This view is aft of the sub panel looking foreward and down

This view is fore of the sub panel looking back.

Sent from my iPhone

On May 18, 2010, at 9:25 PM, "johngoodman" <johngoodman(at)earthlink.net>

wrote:

| Quote: |

>

Installing my panel the other day, I discovered that the maximum

sized hole you can cut in the sub-panel for the radio rack

(according to page 41-4) is insufficient for four typical radio rack

components. Yet, I have seen many panels on display that have been

able to accomplish this feat.

Before I go back to the drawing board, I need an honest answer from

somebody on how this can be accomplished - without compromising the

structural integrity required on 41-4.

Here's the situation: PS 9000X, 430W, SL-40, GTX-330. They all stick

through the sub-panel (the PS doesn't, but try putting a connector

on the back with a turn radius). The real issue is the bottom inch

or so of the sub-panel has to be cut for the GTX-330 to fit, unless

you move the entire stack to the absolute top of the panel, which

brings up other unwanted issues.

Cutting that bottom inch is unthinkable, but it's obvious some of

you have found a way around this. What is it? I had a friend suggest

a "C" channel all the way across the bottom of the sub-panel flange,

where only the tiny flange is still intact. Assuming this is good

engineering, has it been done?

I realize some folks will want to hedge on this, but I'd appreciate

any "hear-say" that you might have heard....

Respectfully,

John

--------

#40572 QB. Working on Cowling & Panel

N711JG reserved

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=298130#298130

|

<pre><b><font size=2 color="#000000" face="courier new,courier">

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

1.25 MB |

| Viewed: |

4735 Time(s) |

|

| Description: |

|

| Filesize: |

1.03 MB |

| Viewed: |

4735 Time(s) |

|

|

|

| Back to top |

|

|

bcondrey

Joined: 03 Apr 2006

Posts: 580

|

Posted: Tue May 18, 2010 7:06 pm Post subject: Need a frank answer Posted: Tue May 18, 2010 7:06 pm Post subject: Need a frank answer |

|

|

Maybe the new versions of the manual are different than mine (original rev 0), the only guidance is that you need to reinforce with 3/4" .063 angle. According to some info I had collected before doing mine, the total stack height you're looking at is 6.88" (I've got the same stack height). The angle technique is actually described on page 41-3 on my revision.

Bob

RV-10 N442PM

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

johngoodman

Joined: 18 Sep 2006

Posts: 530

Location: GA

|

Posted: Wed May 19, 2010 5:29 pm Post subject: Re: Need a frank answer Posted: Wed May 19, 2010 5:29 pm Post subject: Re: Need a frank answer |

|

|

I want to thank everyone for the responses and private messages. I think that I've got a way out, because of the wording on 41-3. It actually says you can skip the lower horizontal angle if you cut below 3/4" of remaining metal; I was assuming that the 3/4" was sacrosanct. It sounds nuts - and I plan on talking with Vans about it - but I'm now guessing that my friend's idea of an angle or "c" channel the length of the very bottom flange would do the trick.

If Vans says differently, I'll let everyone know. Again, thanks for the replies.

John

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

#40572 Phase One complete in 2011 |

|

| Back to top |

|

|

johngoodman

Joined: 18 Sep 2006

Posts: 530

Location: GA

|

Posted: Thu May 20, 2010 3:39 pm Post subject: Re: Need a frank answer Posted: Thu May 20, 2010 3:39 pm Post subject: Re: Need a frank answer |

|

|

Just to close this thread, I talked to tech support at Van's today. Short answer is: It's a VFR airplane, but if you guys want an IFR panel, you will have to cut some metal out of the sub-panel. There is no set rule, but the builder/engineer/god-like-creature must ensure that any resulting weakness due to cutting, is replaced with an equivalent structural integrity.

"nough said - I'm cutting away what I need and putting in some impressive metal support that would make a structural engineer cry (in a good way).

John

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

#40572 Phase One complete in 2011 |

|

| Back to top |

|

|

Phil.Perry(at)netapp.com

Guest

|

Posted: Thu May 20, 2010 3:54 pm Post subject: Need a frank answer Posted: Thu May 20, 2010 3:54 pm Post subject: Need a frank answer |

|

|

I noticed the ones that Bob Newman at TCW put into his RV-10. They look machined and very nice. Too bad they don’t sell them.

I think you could make something out of ¾” angle and do okay. But these sure would be nice.

Here's the link....

http://picasaweb.google.com/rcnewman64/InstrumentPanel#

And a few sneak peeks...

[img]cid:image001.jpg(at)01CAF84D.DE6FF590[/img]

[img]cid:image002.jpg(at)01CAF84D.DE6FF590[/img]

[img]cid:image003.jpg(at)01CAF84D.DE6FF590[/img]

Phil

--

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

4.13 KB |

| Viewed: |

4653 Time(s) |

|

| Description: |

|

| Filesize: |

4.67 KB |

| Viewed: |

4653 Time(s) |

|

| Description: |

|

| Filesize: |

7.52 KB |

| Viewed: |

4653 Time(s) |

|

|

|

| Back to top |

|

|

pitts_pilot(at)bellsouth.

Guest

|

Posted: Thu May 20, 2010 3:58 pm Post subject: Need a frank answer Posted: Thu May 20, 2010 3:58 pm Post subject: Need a frank answer |

|

|

John, just remember that you'll carry the added weight of the

'impressive metal support' forever. I added a 1/2" aluminum angle where

I wanted the additional stiffness, and it serves as a 'shelf' for the

bottom tray. Also, think about the magnitude of stress (deceleration)

in which your mod would make a difference .......

Linn .... hoping I don't open it up again

do not archive

johngoodman wrote:

| Quote: |

Just to close this thread, I talked to tech support at Van's today. Short answer is: It's a VFR airplane, but if you guys want an IFR panel, you will have to cut some metal out of the sub-panel. There is no set rule, but the builder/engineer/god-like-creature must ensure that any resulting weakness due to cutting, is replaced with an equivalent structural integrity.

"nough said - I'm cutting away what I need and putting in some impressive metal support that would make a structural engineer cry (in a good way).

John

--------

#40572 QB. Working on Cowling & Panel

N711JG reserved

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=298377#298377

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|