|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

bicyclop(at)pacbell.net

Guest

|

Posted: Thu Jan 26, 2012 3:44 pm Post subject: Fuses instead of breakers Posted: Thu Jan 26, 2012 3:44 pm Post subject: Fuses instead of breakers |

|

|

I'll try and find it. I know that Klaus is adamant about having a breaker and not a fuse.

Ed

On 1/25/2012 9:56 AM, Robert L. Nuckolls, III wrote: [quote] At 11:24 AM 1/25/2012, you wrote:

Just one more thing to think about if you are doing this with a Lightspeed ignition. From what I've read, there is some sort of crowbar inside the ignition module to protect it from an overvoltage event. If a fuse is fitted and the crowbar kicks it, you'll not be able to reset it as easily as with a breaker - if you can reach the fuse at all. I've heard of at least one case where an airplane was brought down because it was wired differently than the installation instructions in that regard.

Can you elaborate on what you've read and give us sources?

I'm unaware of any crowbar ov protection built into the

LSE system. Is this called out in any of their published

literature? I found this on the Lightspeed site:

------------------------

Electrical System Requirements

All Plasma CDI systems can be used with 12 or 24 volt electrical systems. Input voltages above 35 volts or reversed polarity can cause system damage.

For this reason it is mandatory that all aircraft using Plasma CD Ignitions are equipped with over-voltage protection in their alternator charging system(s). Over-voltage protection is a requirement for certified aircraft. Power connection must be directly to the battery terminals to avoid voltage spikes and electrical noise. Aluminum should never be used as an electrical conductor for the Plasma CDI. Use only the supplied aircraft quality stranded wire.

Minimum supply voltage for starting is 6.5 Volts.

Minimum operating voltage is 5.5 Volts.

--------------------------

This statement argues against any built-in ov

protection. At the same time, the very wide operating

voltage for the system guarantees that a properly

designed 14v system will NEVER offer a threat to

the LSE system.

I am presently participating in an analysis of

cause and effect for simultaneous failure of

dual LSE systems. Root cause for that event

was a failure to craft a failure tolerant

architecture . . . a design goal which is foundation

for all efforts here on the AeroElectric-List.

It's a certainty that no builder who participates

here on the List will suffer such an event.

Bob . . . [b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Jan 26, 2012 5:02 pm Post subject: Fuses instead of breakers Posted: Thu Jan 26, 2012 5:02 pm Post subject: Fuses instead of breakers |

|

|

At 02:43 PM 1/26/2012, you wrote:

--> AeroElectric-List message posted by: Jeff Page <jpx(at)qenesis.com>

At 04:27 PM 1/25/2012, you wrote:

I merely meant that a 5A fuse and a 5A breaker behave differently, but since

the protection type is not specified, the rule could be interpreted as

a maximum of a 5A fuse.

Oh absolutely. The fact that such a level was

given without an accompanying I(squared)T time

constant goes to suggest the arbitrary nature

of the value. As we've discussed here before,

seeing a 5A number on a protective device

is a small bit of knowledge about how the

device performs. I'd have to go arm-wrestle with

dragons to get a 10A fuse attached to a battery

bus in a TC aircraft . . . but you and I know

that a 10A ATC fuse is faster than a miniature

5A breaker and is . . . therefore . . . a

rational crash safety substitute for always-hot

feeders.

What controls the pump motor . . . a contactor?

The float manufacturer (Montana) supplies the pump and control circuitry

already mounted. The relays are Bosch 12V/20A 0 332 209 137

The diagram shows a 25A pullable breaker feeding the relays. A 1A fuse

protects the relay control wiring. So a pullable breaker would be a

convenient way to deal with a stuck relay or a defective pressure switch. That

is perhaps what I should do.

Agreed. Those relays are not specifically

crafted for motor control service. Having

a crew-operated means by which a runaway

can be controlled seems prudent.

I will be interested in the results of your discussions with Klaus

about powering the Lightspeed ignition. I know two people who are

about to install these.

There are no doubt many hundreds if not

thousands of these flying. To the best of my

knowledge, they are not "special" devices

deserving of extra-ordinary attention.

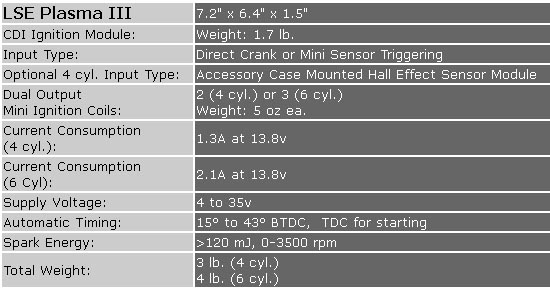

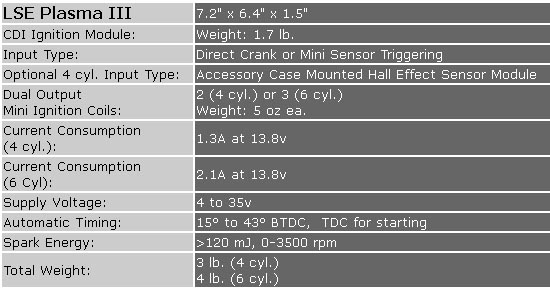

Discussions not withstanding, the published

current draw values for LSE products say that

the greatest current draw for a 6-cylinder

system is 2.1A at 13.8 volts.

[img]cid:.0[/img]

Given that the device features a switchmode power

supply with a wide range of operating voltages,

we know that this is a constant-power mode of

operation. So 2.1 x 13.8 sez the critter needs

right at 30 watts for operation at MAX RPM. One

can expect the current to climb as voltage goes

down . . . so if you're operating battery only

and the battery is down on that 11-volt-slide-

to-darkness, the ignition system current will

have risen to something around 2.7 amps.

Likewise, operating current on a 29 volt bus

will be down around 1.0 amps. The 4-Cylinder

systems are still more frugal in their demands

on the electrical system.

Thanks again for all the great advice. Even while lurking, I learn

something new and useful every week !

Thanks for getting involved and asking. It's

through EXCHANGES of observation and events that

I learn useful things too. Folks have often

asked why the 'Connection is up to Revision 12

in "just 23 years of publication". I tell

them that my education came from a collaboration

with colleagues who spoke engineereze. And we

hammered on a different class of airplane. When I

sat down to do the first chapters of the

'Connection, I realized that I could not answer

questions without knowing what the questions

are. Further, they needed to be written in

OBAMeze.

It's the collective participation of all

the builders on the List/emails/telephone/

seminars that drive what goes into the

next revision. It's truly a work in progress

that would not have happened without this

join venture arena.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

85.1 KB |

| Viewed: |

12421 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Jan 26, 2012 5:21 pm Post subject: Fuses instead of breakers Posted: Thu Jan 26, 2012 5:21 pm Post subject: Fuses instead of breakers |

|

|

| Quote: | Without getting into the discussion of whether the design should or

shouldn't be modified, my purpose on posting (now and back in early

2009) is simply to make those with dual LSE ignition setups aware

that fuses can't be arbitrarily substituted for CBs in this case.

|

I would agree that when the installed system is

at risk for an event triggered by conditions

of installation and/or manufacturing mod levels

then the system is indeed still 'experimental'.

Now that the 'student installer' has graduated

from the lab to the working environment, I'll

suggest that the risk for substitution is

microscopically low.

This is something that we must always keep in

mind. Instructions and ratings are important.

When in doubt, go measure it. It's entirely

possible that the builder who experienced this

event might not have survived to give us his

particular dark-n-stormy-night narrative.

We wouldn't be having this discussion about that

particular event . . . indeed we wouldn't even

know the details.

But the fact is that he DID experience a trip in

a critical system power feeder which prompted further

investigation and he shared his discovery with

the rest of us. That information goes to making

us MORE confident, not less.

I recall a discussion here on the list a some

time back where wires in the wreckage were found

pulled out of the terminal crimps. Hmmm . . .

we'll never know if this failure-to-follow the

instructions precipitated the event . . . but

the overt evidence of failure in craftsmanship

does raise valid questions.

So if one chooses to explore departures from

published instructions, any such departure needs

to be considered carefully. It's not difficult,

just rigorous. Get on the List and let's talk

about it. Bundle all the concerns together and

develop a plan to morph an experiment into a

recipe for success.

But if you don't want to be an explorer or

crafter of new recipes, that's fine too. The

vast majority of our brothers building OBAM

aircraft are not explorers and the last thing

they want to do is experiment. This venue for

acquiring a personally owned aircraft recognizes

that too. Most never frequent this List and

don't need to . . . their relationship with

their airplane's electrical system is no

different than the average spam can driver

in a 172 . . . and that's okay.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Tundra10

Joined: 14 Jun 2010

Posts: 102

Location: Scarborough, Ontario

|

Posted: Fri Jan 27, 2012 11:51 am Post subject: Fuses instead of breakers Posted: Fri Jan 27, 2012 11:51 am Post subject: Fuses instead of breakers |

|

|

| Quote: | >......Are there any other reasons why a pullable circuit breaker

would be >preferred for this situation ?

There are two seperate potential issues here. First, is there an

alternate source

of hydraulic pressure? If you have a practical hand pump available, then

the nuisance trip issue is just that. If the electric pump is your

only practical

source of hydraulic power, then things are a little different. I

could envision

a scenario where the motor for the hydraulic pump has degraded such that

the current draw trips the circuit protection, leaving you with a

gear up landing,

or potentially worse, a partial gear landing. Personally, I would prefer

resettable circuit protection in that scenario.

|

There is a manual hand pump, so no emergency is created.

| Quote: | "I have had to do one inflight reset on the Plasma III on one system

once. The reset was successful and power was restored to the unit. I

removed the unit and sent it back to Klaus for inspection. The fault

was determined to be an overheat situation. That unit was located in

an area without any real ventilation and without an form of cooling

while operation in Arizona during the summer. the compartment temp

was estimated to have exceeded 200 deg. F. The unit was modified to

the latest version (lower heat output components and a ventilation

port. The aircraft was modified to provide air circulation in that

compartment. After 300+ hours on that unit no faults noted. The

point, when the unit faulted it tripped the CB and was then reset

and provided service throughout the remainder of that flight. "

|

Hmmm. If it immediately resumed functioning after resetting the

breaker, perhaps

the ignition never failed, but the heat (and probably higher currents

operating at

high temperatures) caused the breaker to nuisance trip.

| Quote: | I will be interested in the results of your discussions with Klaus

about powering the Lightspeed ignition. I know two people who are

about to install these.

There are no doubt many hundreds if not

thousands of these flying. To the best of my

knowledge, they are not "special" devices

< deserving of extra-ordinary attention.

|

They just get extra attention since pilots are more concerned with their

ignition failing than say their nav lights going out

| Quote: | The relays are Bosch 12V/20A 0 332 209 137

Those relays are not specifically

crafted for motor control service. Having

a crew-operated means by which a runaway

can be controlled seems prudent.

|

A pullable breaker would stop current flow caused by a stuck relay,

and the manual pump could be used to operate the gear, so there is

no significant flight risk.

Those relays do look undersized to me.

Better relays might reduce long term maintenance however. Or perhaps

just carry a spare along might be the most practical approach. I think

the latter ?

Jeff Page

Dream Aircraft Tundra #10

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Jan 27, 2012 12:43 pm Post subject: Fuses instead of breakers Posted: Fri Jan 27, 2012 12:43 pm Post subject: Fuses instead of breakers |

|

|

There is a manual hand pump, so no emergency is created.

Then a robust fuse solution goes toward a cleaner

panel and possibly a cleaner plan B. When THIS

happens, do THAT . . . every time.

>"I have had to do one inflight reset on the Plasma III on one system

>once. The reset was successful and power was restored to the unit. I

>removed the unit and sent it back to Klaus for inspection.

> . . .<snip>

>The point, when the unit faulted it tripped the CB and was then reset

>and provided service throughout the remainder of that flight."

Hmmm. If it immediately resumed functioning after resetting the

breaker, perhaps the ignition never failed, but the heat (and probably

higher currents operating at high temperatures) caused the breaker

to nuisance trip.

The keyword here is "nuisance". I've had to cut the

TC guys some slack for being somewhat submissive to

nuisance trips . . . to strive for the elegant solution

can sometimes be very time consuming and expensive.

One is well advised to trade off cost/benefit ratios.

In the OBAM aircraft world, we're not only able, we are

encouraged to refine any system's configuration in way

that increases the displacement between it's experimental

roots and an enduring recipe for success.

But when one gets a 'nuisance trip' with current protection

that is nearly 2.5 times the published draw numbers . . .

there are reasons to seek answers to some serious questions.

There is a clash of postulates which beg resolution.

They just get extra attention since pilots are more concerned with their

ignition failing than say their nav lights going out

ABSOLUTELY! Which is why I've recommended that electrically

dependent engine accessories drive from always hot battery

bus with totally independent power paths. If two ignition

systems require power and two batteries are available, then

split the systems between the batteries.

But when a 2A device trips a 5A breaker . . . well . . .

A pullable breaker would stop current flow caused by a stuck relay,

and the manual pump could be used to operate the gear, so there is

no significant flight risk.

Great.

Those relays do look undersized to me.

Better relays might reduce long term maintenance however. Or perhaps

just carry a spare along might be the most practical approach. I think

the latter ?

I thought we were talking about a much larger

hydraulic system. The amount of snort needed to

operate the gear in floats is much smaller than

that used on a GlasAir or Lancair. I think these

relays will be fine and since you have a backup

hand pump, your risks are quite low.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jbr79r(at)yahoo.com

Guest

|

Posted: Fri Jan 27, 2012 3:37 pm Post subject: Fuses instead of breakers Posted: Fri Jan 27, 2012 3:37 pm Post subject: Fuses instead of breakers |

|

|

Hi Bob

I built a cold air induction for my glasair and will have an alternate filtered air when on the ground. I take off with 10 deg of flaps. Could there be a way to sequence this alternate air door with the flaps? When the flaps come up the the door opens to allow ram air and when the flaps come down it closes the ram air. Am I getting to complicated?

Jim

James Robinson Glasair lll N79R Spanish Fork UT U77

From: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com>

To: aeroelectric-list(at)matronics.com

Sent: Friday, January 27, 2012 1:40 PM

Subject: Re: Re: Fuses instead of breakers

--> AeroElectric-List message posted by: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)>

There is a manual hand pump, so no emergency is created.

Then a robust fuse solution goes toward a cleaner

panel and possibly a cleaner plan B. When THIS

happens, do THAT . . . every time.

| Quote: | "I have had to do one inflight reset on the Plasma III on one system

once. The reset was successful and power was restored to the unit. I

removed the unit and sent it back to Klaus for inspection.

. . .<snip>

The point, when the unit faulted it tripped the CB and was then reset

and provided service throughout the remainder of that flight."

|

Hmmm. If it immediately resumed functioning after resetting the

breaker, perhaps the ignition never failed, but the heat (and probably

higher currents operating at high temperatures) caused the breaker

to nuisance trip.

The keyword here is "nuisance". I've had to cut the

TC guys some slack for being somewhat submissive to

nuisance trips . . . to strive for the elegant solution

can sometimes be very time consuming and expensive.

One is well advised to trade off cost/benefit ratios.

In the OBAM aircraft world, we're not only able, we are

encouraged to refine any system's configuration in way

that increases the displacement between it's experimental

roots and an enduring recipe for success.

But when one gets a 'nuisance trip' with current protection

that is nearly 2.5 times the published draw numbers . . .

there are reasons to seek answers to some serious questions.

There is a clash of postulates which beg resolution.

They just get extra attention since pilots are more concerned with their

ignition failing than say their nav lights going out

ABSOLUTELY! Which is why I've recommended that electrically

dependent engine accessories drive from always hot battery

bus with totally independent power paths. If two ignition

systems require power and two batteries are available, then

split the systems between the batteries.

But when a 2A device trips a 5A breaker . . . well . . .

A pullable breaker would stop current flow caused by a stuck relay,

and the manual pump could be used to operate the gear, so there is

no significant flight risk.

Great.

Those relays do look undersized to me.

Better relays might reduce long term maintenance however. Or perhaps

just carry a spare along might be the most practical approach. I think

the latter ?

I thought we were talking about a much larger

hydraulic system. The amount of snort needed to

operate the gear in floats is much smaller than

that used on a GlasAir or Lancair. I think these

relays will be fine and since you have a backup

hand pump, your risks

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mrspudandcompany(at)veriz

Guest

|

Posted: Fri Jan 27, 2012 4:56 pm Post subject: Fuses instead of breakers Posted: Fri Jan 27, 2012 4:56 pm Post subject: Fuses instead of breakers |

|

|

Hi Bob

I built a cold air induction for my glasair and will have an

alternate filtered air when on the ground. I take off with 10 deg of flaps.

Could there be a way to sequence this alternate air door with the flaps?

When the flaps come up the the door opens to allow ram air and when the

flaps come down it closes the ram air. Am I getting to complicated?

Jim

Is your alternate air door electrically

operated? If so, you can use a switch, activated by the flaps, to open the

door when flaps are up, and close as soon as flaps are cycled down.

Roger

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

Download |

| Filename: |

winmail.dat |

| Filesize: |

3.92 KB |

| Downloaded: |

748 Time(s) |

|

|

| Back to top |

|

|

jbr79r(at)yahoo.com

Guest

|

Posted: Fri Jan 27, 2012 6:47 pm Post subject: Fuses instead of breakers Posted: Fri Jan 27, 2012 6:47 pm Post subject: Fuses instead of breakers |

|

|

Thanks Roger

It was going to be a simple cable operation, but I thought I would explore other alternatives before making a final decision.

Jim

James Robinson Glasair lll N79R Spanish Fork UT U77

From: ROGER & JEAN CURTIS <mrspudandcompany(at)verizon.net>

To: aeroelectric-list(at)matronics.com

Sent: Friday, January 27, 2012 5:53 PM

Subject: RE: AeroElectric-List: Re: Fuses instead of breakers

Hi Bob

I built a cold air induction for my glasair and will have an

alternate filtered air when on the ground. I take off with 10 deg of flaps.

Could there be a way to sequence this alternate air door with the flaps?

When the flaps come up the the door opens to allow ram air and when the

flaps come down it closes the ram air. Am I getting to complicated?

Jim

Is your alternate air door electrically

operated? If so, you can use a switch, activated by the flaps, to open the

door when flaps are up, and close as soon as flaps are cycled down.

Roger

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

msausen

Joined: 25 Oct 2007

Posts: 559

Location: Appleton, WI USA

|

Posted: Sat Jan 28, 2012 5:53 am Post subject: Fuses instead of breakers Posted: Sat Jan 28, 2012 5:53 am Post subject: Fuses instead of breakers |

|

|

Back when this came up a couple years ago, and Bob C and I discussed possible solutions to this, I did some testing with a 10amp breaker and a 7.5 amp breaker switch. Klaus calls out for power to always be hot from the battery which is not something I am fond of so I figured a switch breaker would be a better choice than two breakers and a switch. In running these two devices in series with the approx length of wire needed, I was able to repeatedly get the breaker switch to "blow" without tripping the 10amp. I know this is a bit of a given but I wanted to see it for myself.

I have a dual LSE3 config and I'm now considering simplifying this by having one off of my vp200 and the other direct to the battery with just a 7.5 amp fuse or breaker. This way if there is a nuisance trip, I can reset via the vp200 and run off a single lse if needed until I land. Of course that still does leave a potential failure mode should both trip and the vp200 connected one not come back online.

Michael

On Jan 26, 2012, at 2:21 PM, "bcondrey" <bob.condrey(at)baesystems.com> wrote:

| Quote: |

FWIW, this subject has been discussed before on the AeroElectric list. Use the search function for the words "Klaus" and "crowbar" and you'll find a couple threads from early 2009. Turns out that it's not just over-voltage events that will cause them to crowbar but apparently over-temp. This was posted on Feb 1, 2009:

"I have had to do one inflight reset on the Plasma III on one system

once. The reset was successful and power was restored to the unit. I

removed the unit and sent it back to Klaus for inspection. The fault

was determined to be an overheat situation. That unit was located in

an area without any real ventilation and without an form of cooling

while operation in Arizona during the summer. the compartment temp

was estimated to have exceeded 200 deg. F. The unit was modified to

the latest version (lower heat output components and a ventilation

port. The aircraft was modified to provide air circulation in that

compartment. After 300+ hours on that unit no faults noted. The

point, when the unit faulted it tripped the CB and was then reset and

provided service throughout the remainder of that flight. "

Without getting into the discussion of whether the design should or shouldn't be modified, my purpose on posting (now and back in early 2009) is simply to make those with dual LSE ignition setups aware that fuses can't be arbitrarily substituted for CBs in this case.

Bob C

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=364895#364895

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bcondrey

Joined: 03 Apr 2006

Posts: 580

|

Posted: Sat Jan 28, 2012 7:36 am Post subject: Re: Fuses instead of breakers Posted: Sat Jan 28, 2012 7:36 am Post subject: Re: Fuses instead of breakers |

|

|

In the spirit of trying to move the ball forward I'll suggest that fusible links to protect the battery feeders are probably the best way to go in a cost/weight/reliability trade. They provide protection of the feeder wires, have a slow time constant so a panel CB will trip first, are inexpensive and lightweight. A larger CB would does the job also but with more weight and cost.

If you've only got a single LSE then maybe no issue since you'll always have a mag to fall back on. If you're running a pair of them however, you need to fully understand failure modes and mitigate the risks. This thread started with the question of whether a fuse would be an adequate substitute for a CB in this application. Given what I believe to be true about the ignitions, the answer is a qualified NO. Qualified because it's only a REAL issue if you don't have a mag to fall back on. Installing as recommended by the manufacturer using a panel mounted CB gives you a solid install. Just make sure you don't do something that compromises that by putting a fuse upstream or substituting a fuse for the panel CB. If you want to protect the feeder use a slightly larger CB or fusible link. You can do a very simple experiment as Michael did to validate the fuse issue (when upstream of a CB).

Bob C

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Jan 28, 2012 7:53 am Post subject: Fuses instead of breakers Posted: Sat Jan 28, 2012 7:53 am Post subject: Fuses instead of breakers |

|

|

At 07:49 AM 1/28/2012, you wrote:

Sausen)" <rvbuilder(at)sausen.net>

Back when this came up a couple years ago, and Bob C and I

discussed possible solutions to this, I did some testing with a 10amp

breaker and a 7.5 amp breaker switch. Klaus calls out for power to

always be hot from the battery which is not something I am fond of so

I figured a switch breaker would be a better choice than two breakers

and a switch. In running these two devices in series with the approx

length of wire needed, I was able to repeatedly get the breaker

switch to "blow" without tripping the 10amp. I know this is a bit of

a given but I wanted to see it for myself.

It's not always a 'given'. Thermally operated feeder protection

have what is called and I(squared)*T constant. Meaning that if

you plot trip times versus fault current, you find that doubling

the fault current produces a trip in 1/4th the time.

Combine this knowledge with the manufacturer's specs for I(squared)*T

for any given device and you can deduce the probability that one

device will trip before the other. But understand too that thermally

activated circuit protection are not "calibrated devices". Look at

the response curves for an exemplar miniature breaker . . .

http://www.aeroelectric.com/Pictures/Curves/Exemplar_Circuit-Breaker_Trip_Response.pdf

For any given fault current combined with ambient temperature

the trip times can vary widely. On top of that variation you

can add "preheat" influences and manufacturing tolerances.

Bottom line is that one should be very cautious about putting

two protective devices in series with any notions about one

tripping before the other.

Your power company has done these studies. As you travel

up the energy-chain from a hair dryer plugged into the

wall to the alternator that provides watt-seconds to dry

your hair, each protective device upstream of any

other protective device is many times more robust.

You don't want the protective device in hair dryer

being over stressed but the whole neighborhood goes

dark instead.

Let's talk design goals:

(1) It's a GOOD thing to be able to cut all power to

every other accessory in the airplane and NOT have

the engine stop. Solution - electronic ignitions

and fuel pumps should power from an always hot

battery bus.

(2) It's a GOOD thing to have always hot wires in

the airplane limited in their ability to produce

fault currents likely to ignite post crash fires.

Solution - protect such feeders at the battery bus

with I(squared)*T constants that reduce such risk

to acceptable levels. Question - what's an acceptable

level? Answer - Don't know from first hand knowledge.

However, folks-who-claim-to-know-more-about-airplanes-

than-we-do have declared that 5A circuit protection

is the golden number.

Exceptions - They did not specify an I(squared)*T

constant for that protection.

What's the prudent system integrator to do? Well,

for starters we can deduce that the exemplar 5A

breaker common to GA, AT, and Military aircraft

is "blessed" so we are on reasonably sound foundation

using that performance for a baseline. What's good

for 100,000 airplanes is good for my RV.

Okay, it's easily demonstrated that a miniature 5A

breaker in series with a 10A ATC fuse will not

open before the fuse does. But what are the risks

for raising the always hot feeder protection to

say 15 or 20A ATC fuse? Who knows? It's a certainty

that some agency would love to have a $million$ budget

to research an answer and then write rules about

it.

So what's a reasonable approach for standing off

the worries amongst those in our numbers who do

worry about it a lot?

I suggest that it is quite simple:

But a bigger fuse in at the battery bus. I don't

care if you go to 20A. 20A wire too? No. We already

KNOW that a 20A steady state current will not burn

a 22AWG wire.

http://aeroelectric.com/Pictures/Wire/22AWG_20A.pdf

So wire with 20AWG or even 18AWG. Remember, we're

talking about crash safety. What is the likelihood

that your 20A/18AWG, always-hot feeder will be

placed in a potential position for setting you

on fire? Very low. Further, keep in mind that an

always hot wire in a wreck may not get hard-faulted

in a way that would open even the 5A breaker. A

soft-fault on a 12 volt battery feeder protected

at 5A is VERY capable of starting fires. So that

5A number goes more to setting rules and stopping

arguments than it does to any scientific hedge

against conflagration.

The rational solution:

(1) I suggest that agonizing over fuse sizes

is a waste of intellectual and emotional

capital. Make the fuse BIG in comparison to system

DEMAND. Make the wire mechanically robust which

makes it QUITE capable of meeting system demands

but not necessarily capable of meeting AC43-13

temperature rise recommendations - you're never going

to load the wire that hard. This is a special

case that does not fit the legacy design goals

for wire/breaker/fuse sizing.

(2) Don't get wrapped around the axle of crash safety.

That problem has been painted with a VERY broad

brush. Better that you crash for reasons

beyond your control than because ignition or fuel

pump supply feeders protection were too light

and the engine quit.

I have a dual LSE3 config and I'm now considering simplifying this by

having one off of my vp200 and the other direct to the battery with

just a 7.5 amp fuse or breaker. This way if there is a nuisance

trip, I can reset via the vp200 and run off a single lse if needed

until I land. Of course that still does leave a potential failure

mode should both trip and the vp200 connected one not come back online.

It's my considered recommendation that the LSE

system not depend on ANY other features in your

power distribution beyond a fuse at the battery

bus (not a breaker . . . we want it to be FAST)

and a switch on the panel. You want to be able

to shut the MASTER off without having the engine

quit. Same thing for your fuel pumps if you have

them.

Remove the term NUISANCE TRIP from the lexicon

of talking about your airplane's electrical systems.

The only circuits that EVER nuisance trip are those

not properly crafted to design goals . . . like

those stated above.

ANY time you hear a hangar-tale or ramp-rumor

about somebody's system tripping but the day was

saved by pushing a breaker back in, then thank

your stars for the fact that you participate

on the AeroElectric-List and folks have helped

you design for robustness. YOUR airplane is not

going to suffer nuisance trips. If it EVER does,

you'll find out why and make appropriate changes

to see that it never happens again. Then you'll

share that event with the rest of us on the List

just in case you've discovered some new condition

that others need to be aware of.

Further, if we do find that an LSE product is

fitted with any sort of CROWBAR ov protection

(which I doubt) then I think it is prudent

to ask that your devices be delivered with that

feature disabled. There is no good reason to

build such a feature into any accessory. Even

LSE says it's mandatory that your SHIP'S SYSTEM

be fitted with ov protection.

Finally, if the foregoing does not give you sufficient

confidence based upon understanding the potential effects

of departing from the manufacturer's recipe for

success, then please follow the manufacture's

recommendations TO THE LETTER. Keeping the engine

running should be the LEAST of your worries.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Jan 28, 2012 8:05 am Post subject: Fuses instead of breakers Posted: Sat Jan 28, 2012 8:05 am Post subject: Fuses instead of breakers |

|

|

At 09:36 AM 1/28/2012, you wrote:

<bob.condrey(at)baesystems.com>

In the spirit of trying to move the ball forward I'll suggest that

fusible links to protect the battery feeders are probably the best

way to go in a cost/weight/reliability trade. They provide protection

of the feeder wires, have a slow time constant so a panel CB will

trip first, are inexpensive and lightweight. A larger CB would does

the job also but with more weight and cost.

Except that they are overly robust and do not even

come close to addressing concerns for crash safety.

A 20A ATC fuse is an excellent middle ground that

offers approximately 10X operational robustness

factor and still reacts quickly to crash induced

hard faults.

There is no good reason to "double up" with breakers

on the panel. Fuses/breaker/limiters/links are to protect

wires. Only ONE is needed between the ignition system's

power source and the electronics. So the up-sized fuse

makes the most sense.

If you've only got a single LSE then maybe no issue since you'll

always have a mag to fall back on. If you're running a pair of them

however, you need to fully understand failure modes and mitigate the risks.

That's what the List is all about . . .

This thread started with the question of whether a fuse would be an

adequate substitute for a CB in this application. Given what I

believe to be true about the ignitions, the answer is a qualified

NO. Qualified because it's only a REAL issue if you don't have a mag

to fall back on.

Are you offered a dual failure hypothesis?

Installing as recommended by the manufacturer using a panel mounted

CB gives you a solid install.

Operationally correct but no consideration

for crash-safety.

Just make sure you don't do something that compromises that by

putting a fuse upstream or substituting a fuse for the panel CB. If

you want to protect the feeder use a slightly larger CB or fusible

link. You can do a very simple experiment as Michael did to validate

the fuse issue (when upstream of a CB).

Don't over-simply such experiments. The devil is

in the details. Better you have ONE protective

device crafted for robustness while not seriously

disregarding crash safety.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Tundra10

Joined: 14 Jun 2010

Posts: 102

Location: Scarborough, Ontario

|

Posted: Sat Jan 28, 2012 10:27 am Post subject: Fuses instead of breakers Posted: Sat Jan 28, 2012 10:27 am Post subject: Fuses instead of breakers |

|

|

| Quote: | I thought we were talking about a much larger

hydraulic system. The amount of snort needed to

operate the gear in floats is much smaller than

that used on a GlasAir or Lancair. I think these

relays will be fine and since you have a backup

hand pump, your risks are quite low.

|

So perhaps 10AWG wire is not required ?

The installation instructions show 12AWG with a 25A pullable breaker.

Many builders are happily flying with this installation.

The hydralic pump motor is a Parker-Oildyne series 108 12VDC permanent

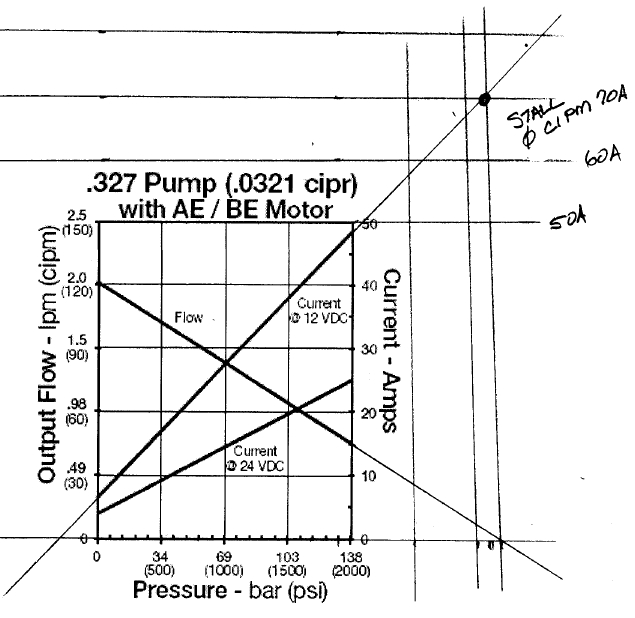

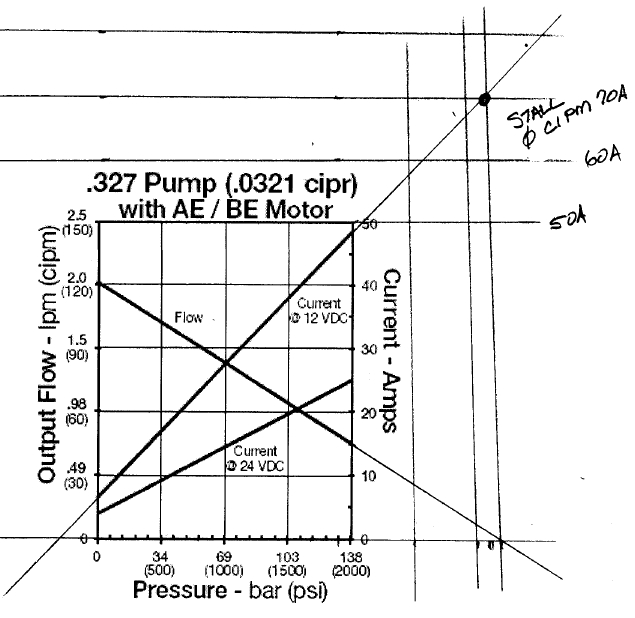

magnet motor code AE 0.327".

The pressure switches are 500psi. I assume this means that there will

be brief spikes above

this pressure at the motor when it first starts up, but after the

fluid is moving, it must be less than 500psi.

Based on the small graph, the current at 500psi is 17A to produce a

flow of 51 cubic inches per minute, but I have no method to estimate

the inrush current as the motor starts up. The graph stops at 2000psi

at 48A continuous (but not for long according to the intermittent use

temperature graph). The successful use of small relays would indicate

the inrush current is not significant ?

I don't know how to estimate the inrush current, nor the amount of

voltage sag that would negatively impact the motor at startup.

So I can't calculate any possible advantages of heavier wire

Jeff Page

Dream Aircraft Tundra #10

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Jan 28, 2012 12:12 pm Post subject: Fuses instead of breakers Posted: Sat Jan 28, 2012 12:12 pm Post subject: Fuses instead of breakers |

|

|

So perhaps 10AWG wire is not required ?

The installation instructions show 12AWG with a 25A pullable breaker.

Many builders are happily flying with this installation.

Well, let's run the numbers and see . . .

The hydralic pump motor is a Parker-Oildyne series 108 12VDC permanent

magnet motor code AE 0.327".

AHA! REAL stick-to-your-grey-matter data. It's amazing

what you can discover if given a few numbers. In this case:

[img]cid:.0[/img]

Okay. The critical numbers here are the cubic inch displacement

per revolution (0.0321). The current at any two flow points which

gives you the slope of the line in PSI/AMP. The point where

pressure goes to zero but flow is max. This point establishes

the internal energy dissipation in motor and pump. We could

develop all the torque and CEMF constants for the motor

in numbers . . . but the questions yield nicely to a

pencil and straight-edge solution too.

I've extended the curves to the point where flow goes to

zero (stall) and current goes to zero (which provides

the anchor point for zero load RPM of the motor. But to

get to THE question of the moment, I deduce that stall

current for this motor is on the order of 70 amps. This

current is EQUAL to that demanded of a 3200 PSI condition

which can never be achieved because of the relief valves.

The pressure switches are 500psi. I assume this means that there will

be brief spikes above this pressure at the motor when it first starts

up, but after the fluid is moving, it must be less than 500psi.

Actually no. Pressure induced motor current is dominant only

after the motor is stable at some speed. During start up, the

flows can be no greater than what the system back pressure

allows and is probably quite low. Motor current is high because

the armature is accelerating to a stable operating point. If

pressure reliefs are set for 500 psi then the maximum operating

current for the motor will be 17A and probably achieved only

when all cylinders reach their limits causing flow resistance

to spike. Only then would we expect the pressure to climb

rapidly for the moon . . . and were it NOT for relief valves,

the current would approach stall or a hose will blow off.

Now, if you started the motor up to FURTHER extend/retract

the gear against hard stops, you get the same 70A inrush

which would fall only to 17A and stay there as the relief valves

cracked. System pressure would never exceed 500 PSI.

Based on the small graph, the current at 500psi is 17A to produce a

flow of 51 cubic inches per minute, but I have no method to estimate

the inrush current as the motor starts up. The graph stops at 2000psi

at 48A continuous (but not for long according to the intermittent use

temperature graph).

Now you know how to do it.

The successful use of small relays would indicate the inrush

current is not significant ?

No, it's always significant.

Keep in mind that system wiring can have a profound

effect on inrush currents. 70A at 12v implies a motor

resistance of 12/70 or 0.17 ohms. 10AWG wire is one

millohm per foot. So adding say 10' of 10AWG in the total

loop resistance takes your motor + wire up to 180

milliohms for a new inrush of 12/.180 or 66 amps. Of

course, this doesn't account for any sag in electrical

system voltage during inrush. 12AWG wire is 1.6 milliohms

per foot so inrush comes down some more.

Since the running current cannot exceed 17A due to

action of relief valves, you COULD consider a 14AWG

or even 16AWG feeder for the purpose of limiting

inrush . . . assuming that becomes a design goal.

This would have no effect on available system pressure

because that is set by relief valves. It WOULD reduce

available flow at that pressure because motor voltage

hence RPM is slightly reduced. Wired per the instructions,

it seems that your inrush will be on the order of 50-65

amps which is no big deal on a 30A relay.

I don't know how to estimate the inrush current, nor the amount of

voltage sag that would negatively impact the motor at startup.

So I can't calculate any possible advantages of heavier wire

The 'advantages' if any are murky. The system you're installing

has a successful track record with components specified

by the manufacturer. I can see no compelling reason

to alter that recipe.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

156.45 KB |

| Viewed: |

12390 Time(s) |

|

|

|

| Back to top |

|

|

Tundra10

Joined: 14 Jun 2010

Posts: 102

Location: Scarborough, Ontario

|

Posted: Sun Jan 29, 2012 8:52 am Post subject: Fuses instead of breakers Posted: Sun Jan 29, 2012 8:52 am Post subject: Fuses instead of breakers |

|

|

Bob,

Thank you ever so much for your analysis, and your time that you

obviously took to teach it. I was looking at that graph, thinking it

appeared they were providing lots of information, yet it seemed

insufficient.

Now that you have taught me how easy it is to extend the lines, I am

disappointed I didn't think of that myself, but now I can use that

technique to great benefit in the future.

Also very important, is that I can wire my aircraft, _knowing_ that

the installation is the best possible compromise of all the factors,

rather than blindly following the installation instructions of a

company who's expertise is building floats, rather than electrical

design.

In this case, your analysis confirms their installation instructions

are excellent, providing confidence that they offer a solid product.

Thanks !!

Jeff Page

Dream Aircraft Tundra #10

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

natsuto

Guest

|

Posted: Tue Feb 14, 2012 6:03 pm Post subject: Re: Fuses instead of breakers Posted: Tue Feb 14, 2012 6:03 pm Post subject: Re: Fuses instead of breakers |

|

|

I promptly pull the hangar and wired directly to the battery Klaus's instructions. I've always wanted, he wrote: There is a reason. Has been working ever since.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Feb 15, 2012 6:35 am Post subject: Fuses instead of breakers Posted: Wed Feb 15, 2012 6:35 am Post subject: Fuses instead of breakers |

|

|

At 08:03 PM 2/14/2012, you wrote:

| Quote: |

I promptly pull the hangar and wired directly to the battery Klaus's

instructions. I've always wanted, he wrote: There is a reason. Has

been working ever since.

|

When one is unsure of elegant alternatives

to common sense design goals, it is good to follow

the manufacturer's instructions.

At the same time, the manufacturer's instructions

my be only one of several recipes for success.

This is how the "experimental" airplane becomes

a teaching tool where new recipes can be considered

and proven. Just as the student in the chemistry

lab is learning by 'experiment' the teacher knows the

outcome of every lesson. For the teacher, the lab

is a tool to share recipes and the behavior of

their ingredients . . . anything but an experiment.

For the student, the experience morphs an experiment

into useful knowledge and skills. The next time that

recipe is repeated, the outcome is predictable.

At the same time, the teacher is ever mindful of

individual willingness to expand on their experimental

experiences. The explorer is well advised to temper

their quest for discovery with any admonition the

teacher may offer like, "Don't do that! You'll set

the lab on fire . . . or put your eye out!"

The word experimental is synonymous with explore

and discovery. But just as the automotive industry

is discovering that the lithium battery may not

yet be ready for prime time (perhaps influenced

by institutional pressure to 'hurry up and save

the planet'?) they have learned a lot and are still

in the discovery phase.

In experimental aviation we have a rich

library of historical successes (and failures)

to study. The trick is to shun any form of

pressure, be it institutional or from the hangar

mate next door. In experimental aviation we need

not "launch any new recipe into the sky before it's

time."

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|