|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

henador_titzoff(at)yahoo.

Guest

|

Posted: Thu May 17, 2012 11:03 am Post subject: Anti Corrosive Zinc Paste Posted: Thu May 17, 2012 11:03 am Post subject: Anti Corrosive Zinc Paste |

|

|

Hi People,

I would like to know what opinions you have on anti-corrosive zinc paste to make our connections more reliable. Below is a link to an article on how ACZP helps make better connections by supplying sacrificial zinc ions to stop or decrease corrosion at the push on connector's mechanical linkage, which actually supplies the electrical connection. The two pastes he mentions, Burndy Penetrox and Ideal Noalox, seem to do the job but are either too far on the right or left when it comes to consistency. Do you guys think that ACZP will help with our normal push on connectors that we use in aviation, and/or do you have a product recommendation that is better than these two products? I do have an application to wire lights on a large road trailor, and I would like to use ACZP on those connections, since road surfaces can be covered with all sorts of nasty corrosive substances. Perhaps a ACZP can have a good application there to keep out all the nasties. What do you guys think? Eric, you're pretty good on surfaces corroding. What do you think? You, too, Bob.

http://sw-em.com/anti_corrosive_paste.htm

Thanks.

Henador Titzoff

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu May 17, 2012 11:37 am Post subject: Anti Corrosive Zinc Paste Posted: Thu May 17, 2012 11:37 am Post subject: Anti Corrosive Zinc Paste |

|

|

The article states in part:

Why anyone would want to apply an insulating grease on a place where you want a good electrical connection is beyond me

Simple: The "insulating grease" is not intended as an enhancement

to conductivity but an protectant from environmental intrusion.

Think of it as a kind of brush-on potting compound.

. . . because if it got between the contacts, it would actually be degrading the connection,

Okay, let's explore that statement. When you're mating up two

metallic conductors, the ideal joint is represented by the

crimped-on terminal where the two metals are deformed into each

other by applying forces that cause the metals to fail in compression.

I.e., they are literally molded into one piece. What's

the compression strength of copper? Compare that to the compression

strength of silicon grease. The idea that any grease would remain

within the mate-up of the two metals is simply not supported by

facts. Now, the extruded grease will remain in place just outside

the volume where the two conductors became one. This residual grease

that protects the joint from incursion of antagonistic moisture

and gasses.

A similar but less violent joining happens when you mash a

terminal down on a stud. Where the two metals join, they

conform to each other and the grease is extruded out of the

joint.

Irrespective of the 'magic' qualities of any joint additive

for electrical connections, the joint NEVER gets any better

than it was right after two, clean conductors were properly

mated to each other for the first time. Whether it maintains

that integrity is a not a function of keeping the electrons

in but keeping the nasties out. Good ol' Dow Corning DC-4 or

similar does that quite nicely.

Back when I used to climb towers for a living, coax connectors

were often mated after packing the contact cavity with DC-4.

The stuff oozed out of the mated connector. Never saw or heard

of a connector so-treated becoming electrically unreliable or

mechanically corroded. To understand how that stuff works

you need to imagine yourself 0.00001" tall, standing just

outside a new joint and watching what happens as the ratchet

handles are closed, the nut driver twisted or the connector

back shell being spun down tight.

No magic, just ordinary strength of materials.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

henador_titzoff(at)yahoo.

Guest

|

Posted: Thu May 17, 2012 3:02 pm Post subject: Anti Corrosive Zinc Paste Posted: Thu May 17, 2012 3:02 pm Post subject: Anti Corrosive Zinc Paste |

|

|

Well, he does admit that his ACZP is also an insulation grease, but it has zinc in it, acting as sacrificial anodes; therefore, the only difference is the zinc.

Does everyone agree that insulating grease will increase reliability due to its ability to keep corroding agents out? If corroding agents start at the periphery of where the two metals are slammed together to form the conducting surface, the grease can serve to stop the corrosion before it eats away at the conducting surface. Maybe I'm worried about a problem that doesn't exist, but I have an application where the slide on connectors are going to be exposed to highway conditions. over a period of years. Maybe I should be using butt connectors with shrink tubing instead?

Henador Titzoff

From: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com>

To: aeroelectric-list(at)matronics.com

Sent: Thursday, May 17, 2012 3:36 PM

Subject: Re: Anti Corrosive Zinc Paste

The article states in part:

Why anyone would want to apply an insulating grease on a place where you want a good electrical connection is beyond me

Simple: The "insulating grease" is not intended as an enhancement

to conductivity but an protectant from environmental intrusion.

Think of it as a kind of brush-on potting compound.

. . . because if it got between the contacts, it would actually be degrading the connection,

Okay, let's explore that statement. When you're mating up two

metallic conductors, the ideal joint is represented by the

crimped-on terminal where the two metals are deformed into each

other by applying forces that cause the metals to fail in compression.

I.e., they are literally molded into one piece. What's

the compression strength of copper? Compare that to the compression

strength of silicon grease. The idea that any grease would remain

within the mate-up of the two metals is simply not supported by

facts. Now, the extruded grease will remain in place just outside

the volume where the two conductors became one. This residual grease

that protects the joint from incursion of antagonistic moisture

and gasses.

A similar but less violent joining happens when you mash a

terminal down on a stud. Where the two metals join, they

conform to each other and the grease is extruded out of the

joint.

Irrespective of the 'magic' qualities of any joint additive

for electrical connections, the joint NEVER gets any better

than it was right after two, clean conductors were properly

mated to each other for the first time. Whether it maintains

that integrity is a not a function of keeping the electrons

in but keeping the nasties out. Good ol' Dow Corning DC-4 or

similar does that quite nicely.

Back when I used to climb towers for a living, coax connectors

were often mated after packing the contact cavity with DC-4.

The stuff oozed out of the mated connector. Never saw or heard

of a connector so-treated becoming electrically unreliable or

mechanically corroded. To understand how that stuff works

you need to imagine yourself 0.00001" tall, standing just

outside a new joint and watching what happens as the ratchet

handles are closed, the nut driver twisted or the connector

back shell being spun down tight.

No magic, just ordinary strength of materials.

Bob . . .

[quote]http://www.matronics.com/Navigator?AeroElectric--============================================

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Bob McC

Joined: 09 Jan 2006

Posts: 258

Location: Toronto, ON

|

Posted: Thu May 17, 2012 3:02 pm Post subject: Anti Corrosive Zinc Paste Posted: Thu May 17, 2012 3:02 pm Post subject: Anti Corrosive Zinc Paste |

|

|

Henador;

Bear in mind that both of the proprietary products you mention are specifically manufactured for preventing the corrosion of Aluminium wiring connections so they should be particularly effective at keeping oxygen out of the joint. When making crimped connections on Aluminium Hydro transmission lines the process was to strip the insulation, brush the conductors bright with a stainless steel brush, dip the wire into the pot of Penetrox, and then install the connector with a hydraulic crimper. Never heard of a failure of any joints done this way even in the rather harsh environment of the mining industry.

Bob McC

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Henador Titzoff

Sent: Thursday, May 17, 2012 3:01 PM

To: aeroelectric-list(at)matronics.com

Subject: Anti Corrosive Zinc Paste

Hi People,

I would like to know what opinions you have on anti-corrosive zinc paste to make our connections more reliable. Below is a link to an article on how ACZP helps make better connections by supplying sacrificial zinc ions to stop or decrease corrosion at the push on connector's mechanical linkage, which actually supplies the electrical connection. The two pastes he mentions, Burndy Penetrox and Ideal Noalox, seem to do the job but are either too far on the right or left when it comes to consistency. Do you guys think that ACZP will help with our normal push on connectors that we use in aviation, and/or do you have a product recommendation that is better than these two products? I do have an application to wire lights on a large road trailor, and I would like to use ACZP on those connections, since road surfaces can be covered with all sorts of nasty corrosive substances. Perhaps a ACZP can have a good application there to keep out all the nasties. What do you guys think? Eric, you're pretty good on surfaces corroding. What do you think? You, too, Bob.

http://sw-em.com/anti_corrosive_paste.htm

Thanks.

Henador Titzoff

| Quote: | | http://www.matronics.com/Navigator?AeroElectric-List |

0123456789

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Bob McC

Falco #908

(just starting) |

|

| Back to top |

|

|

raymondj(at)frontiernet.n

Guest

|

Posted: Thu May 17, 2012 3:47 pm Post subject: Anti Corrosive Zinc Paste Posted: Thu May 17, 2012 3:47 pm Post subject: Anti Corrosive Zinc Paste |

|

|

Myself and many of my associates use dielectric grease on our trailers

and boats. Anecdotal experience has been that it is beneficial, and at

a minimum, does no harm.

Raymond Julian

Kettle River, MN

"And you know that I could have me a million more friends,

and all I'd have to lose is my point of view." - John Prine

On 05/17/2012 05:59 PM, Henador Titzoff wrote:

| Quote: | Well, he does admit that his ACZP is also an insulation grease, but it

has zinc in it, acting as sacrificial anodes; therefore, the only

difference is the zinc.

Does everyone agree that insulating grease will increase reliability due

to its ability to keep corroding agents out? If corroding agents start

at the periphery of where the two metals are slammed together to form

the conducting surface, the grease can serve to stop the corrosion

before it eats away at the conducting surface. Maybe I'm worried about a

problem that doesn't exist, but I have an application where the slide on

connectors are going to be exposed to highway conditions. over a period

of years. Maybe I should be using butt connectors with shrink tubing

instead?

Henador Titzoff

------------------------------------------------------------------------

*From:* "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com>

*To:* aeroelectric-list(at)matronics.com

*Sent:* Thursday, May 17, 2012 3:36 PM

*Subject:* Re: Anti Corrosive Zinc Paste

> What do you think? You, too, Bob.

>

> http://sw-em.com/anti_corrosive_paste.htm

The article states in part:

*Why anyone would want to apply an /insulating/ grease on a place where

you want a good electrical connection is beyond m**e

*Simple: The "insulating grease" is not intended as an enhancement

to conductivity but an protectant from environmental intrusion.

Think of it as a kind of brush-on potting compound.

*. . . because if it got between the contacts, it would actually be

degrading the connection,

*Okay, let's explore that statement. When you're mating up two

metallic conductors, the ideal joint is represented by the

crimped-on terminal where the two metals are deformed into each

other by applying forces that cause the metals to fail in compression.

I.e., they are literally molded into one piece. What's

the compression strength of copper? Compare that to the compression

strength of silicon grease. The idea that any grease would remain

within the mate-up of the two metals is simply not supported by

facts. Now, the extruded grease will remain in place just outside

the volume where the two conductors became one. This residual grease

that protects the joint from incursion of antagonistic moisture

and gasses.

A similar but less violent joining happens when you mash a

terminal down on a stud. Where the two metals join, they

conform to each other and the grease is extruded out of the

joint.

Irrespective of the 'magic' qualities of any joint additive

for electrical connections, the joint NEVER gets any better

than it was right after two, clean conductors were properly

mated to each other for the first time. Whether it maintains

that integrity is a not a function of keeping the electrons

in but keeping the nasties out. Good ol' Dow Corning DC-4 or

similar does that quite nicely.

Back when I used to climb towers for a living, coax connectors

were often mated after packing the contact cavity with DC-4.

The stuff oozed out of the mated connector. Never saw or heard

of a connector so-treated becoming electrically unreliable or

mechanically corroded. To understand how that stuff works

you need to imagine yourself 0.00001" tall, standing just

outside a new joint and watching what happens as the ratchet

handles are closed, the nut driver twisted or the connector

back shell being spun down tight.

No magic, just ordinary strength of materials.

Bob . . .

*http://www.matronics.com/Navigator?AeroElectric--============================================

<http://www.matronics.com/Navigator?AeroElectric-List> <http://www.matronics.com/Navigator?AeroElectric-List>*

<http://www.matronics.com/Navigator?AeroElectric-List>

<http://www.matronics.com/Navigator?AeroElectric-List>

<http://www.matronics.com/Navigator?AeroElectric-List>

*

*

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

john.maccallum(at)bigpond

Guest

|

Posted: Thu May 17, 2012 11:13 pm Post subject: Anti Corrosive Zinc Paste Posted: Thu May 17, 2012 11:13 pm Post subject: Anti Corrosive Zinc Paste |

|

|

I used Penetrox on a 9El Log Periodic for 13-29 mhz and also on 2 x 13 EL Long Boom 2m Yagis. Up in the Air for about 5 years.

The joints out lasted the feedlines after the White Cockatoos got them L

Cheers

John MacCallum

RV10 41016

VH-DUU

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Bob McCallum

Sent: Friday, 18 May 2012 9:00 AM

To: aeroelectric-list(at)matronics.com

Subject: RE: Anti Corrosive Zinc Paste

Henador;

Bear in mind that both of the proprietary products you mention are specifically manufactured for preventing the corrosion of Aluminium wiring connections so they should be particularly effective at keeping oxygen out of the joint. When making crimped connections on Aluminium Hydro transmission lines the process was to strip the insulation, brush the conductors bright with a stainless steel brush, dip the wire into the pot of Penetrox, and then install the connector with a hydraulic crimper. Never heard of a failure of any joints done this way even in the rather harsh environment of the mining industry.

Bob McC

From: owner-aeroelectric-list-server(at)matronics.com (owner-aeroelectric-list-server(at)matronics.com) [mailto:owner-aeroelectric-list-server(at)matronics.com (owner-aeroelectric-list-server(at)matronics.com)] On Behalf Of Henador Titzoff

Sent: Thursday, May 17, 2012 3:01 PM

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Subject: Anti Corrosive Zinc Paste

Hi People,

I would like to know what opinions you have on anti-corrosive zinc paste to make our connections more reliable. Below is a link to an article on how ACZP helps make better connections by supplying sacrificial zinc ions to stop or decrease corrosion at the push on connector's mechanical linkage, which actually supplies the electrical connection. The two pastes he mentions, Burndy Penetrox and Ideal Noalox, seem to do the job but are either too far on the right or left when it comes to consistency. Do you guys think that ACZP will help with our normal push on connectors that we use in aviation, and/or do you have a product recommendation that is better than these two products? I do have an application to wire lights on a large road trailor, and I would like to use ACZP on those connections, since road surfaces can be covered with all sorts of nasty corrosive substances. Perhaps a ACZP can have a good application there to keep out all the nasties. What do you guys think? Eric, you're pretty good on surfaces corroding. What do you think? You, too, Bob.

http://sw-em.com/anti_corrosive_paste.htm

Thanks.

Henador Titzoff

012345678901234567

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

mrspudandcompany(at)veriz

Guest

|

Posted: Fri May 18, 2012 4:09 am Post subject: Anti Corrosive Zinc Paste Posted: Fri May 18, 2012 4:09 am Post subject: Anti Corrosive Zinc Paste |

|

|

The joints out lasted the feedlines after the White Cockatoos got them L

Over the years I have lost a lot of sleep, wondering if the Cockatoos, especially

The White ones, were eating my radio antenna feed lines. So far I have seen no

Signs of damage from the critters, but I will continue to be vigilant and keep

My aircraft locked at all times to be safe. ☺ ☺ ☺

Roger

Do Not Archive

[quote]

href="http://www.matronics.com/Navigator?AeroElectric-List">http://www.matronics.com/Navigator?AeroElectric-List

href="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/c

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Fri May 18, 2012 5:07 am Post subject: Re: Anti Corrosive Zinc Paste Posted: Fri May 18, 2012 5:07 am Post subject: Re: Anti Corrosive Zinc Paste |

|

|

Henador;

As Bob and others have said, ACZP, which is probably zinc oxide + silicone grease, has the merits of keeping environmentals out of the joint while also transferring heat. The glop used to stick your microprocessor to its heat sink is usually zinc oxide/silicone grease.

Many substances make good electrical joint sealant, and yes, putting insulating grease on a conductive joint makes perfect sense, since the grease only replaces existing insulating air gaps. Sometimes people use silver paste, but not because it's electrically conductive--silver is a better heat conductor.

Why any notion of zinc being "sacrificial" comes up is beyond me. You certainly wouldn't want to use it if it was.

The only reason not to use it is that it is messy. Otherwise it would be everywhere.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

henador_titzoff(at)yahoo.

Guest

|

Posted: Fri May 18, 2012 3:37 pm Post subject: Anti Corrosive Zinc Paste Posted: Fri May 18, 2012 3:37 pm Post subject: Anti Corrosive Zinc Paste |

|

|

Thank you for weighing in, Eric. When attaching connectors to wires in avionics and automotive applications, there isn't a need for increasing heat transfer, so zinc is not needed. A simple dielectric grease is sufficient, you say. This is pretty much what Bob says, so I'll run with it.

There are several posts from people about this, and I see two more that I haven't read. Let me see what they say and hopefully one of them will stand out on a recommended good grease at a good price and readily available.

Thanks,

Henador Titzoff

From: Eric M. Jones <emjones(at)charter.net>

To: aeroelectric-list(at)matronics.com

Sent: Friday, May 18, 2012 9:07 AM

Subject: Re: Anti Corrosive Zinc Paste

--> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net (emjones(at)charter.net)>

Henador;

As Bob and others have said, ACZP, which is probably zinc oxide + silicone grease, has the merits of keeping environmentals out of the joint while also transferring heat. The glop used to stick your microprocessor to its heat sink is usually zinc oxide/silicone grease.

Many substances make good electrical joint sealant, and yes, putting insulating grease on a conductive joint makes perfect sense, since the grease only replaces existing insulating air gaps. Sometimes people use silver paste, but not because it's electrically conductive--silver is a better heat conductor.

Why any notion of zinc being "sacrificial" comes up is beyond me. You certainly wouldn't want to use it if it was.

The only reason not to use it is that it is messy. Otherwise it would be everywhere.

--------

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net

Read this topic online here:

http://forums.matronics.co="http://www.matronics.com/Navigator?AeroElectric-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List========================

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun May 20, 2012 7:48 am Post subject: Anti Corrosive Zinc Paste Posted: Sun May 20, 2012 7:48 am Post subject: Anti Corrosive Zinc Paste |

|

|

| Quote: | | There are several posts from people about this, and I see two more that I haven't read. Let me see what they say and hopefully one of them will stand out on a recommended good grease at a good price and readily available. |

I would suggest the use of ductile sealants on joints that

are exposed to most severe combinations of contaminants+water+

heat. Battery terminals come to mind. Joints that are made up

once and expected to run the lifetime of the airplane (crimped

terminals, fat-wire connections to accessories, busses, etc)

and not splashed or gassed are generally fine without added

insurance.

While I was working at Cessna, I recall an optional 'corrosion

resistant' treatment that was offered to individuals who lived

on the coasts, and owners of planes on floats or agricultural

spray planes. Over the years, there have been numerous spray-

on treatments for the interior surfaces of aluminum airplanes

with a notion of slowing corrosion. But all of these offsets

were directed at structural corrosion issues as opposed to

the make up of a joint between two conductors in the electrical

system.

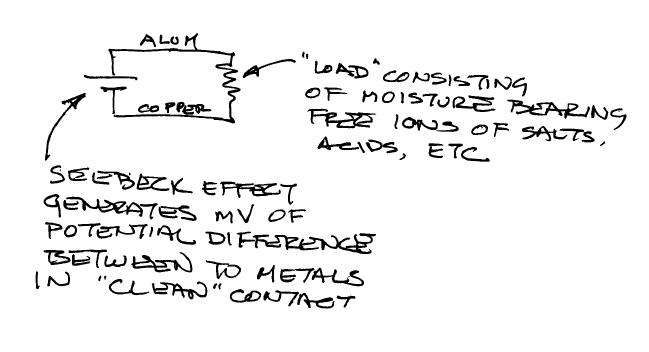

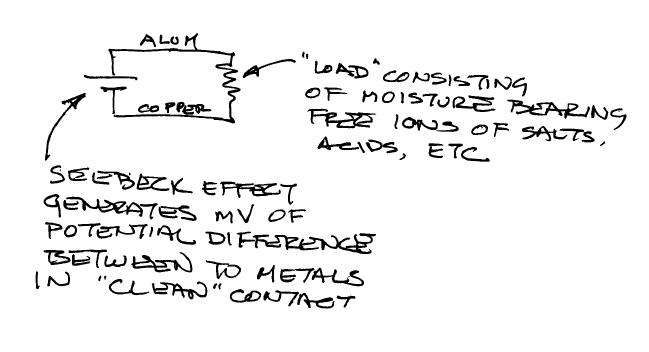

Intrusion of conductive moisture is antagonistic to the

copper/aluminum joint right at the edges of the joint. Usually

right under the terminal flag, out of sight but also not gas-

tight to the environment.

[img]cid:.0[/img]

For all the concerns about fending off oxidation of metals

on the aircraft structure, I don't recall ever reading about

a generalized treatment of electrical components beyond the

use of tin plated terminals to take a ground wire down to

an aluminum skin. The value of this process is illustrated

here:

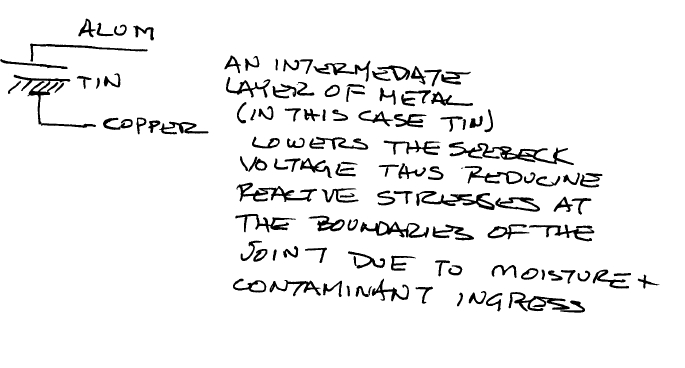

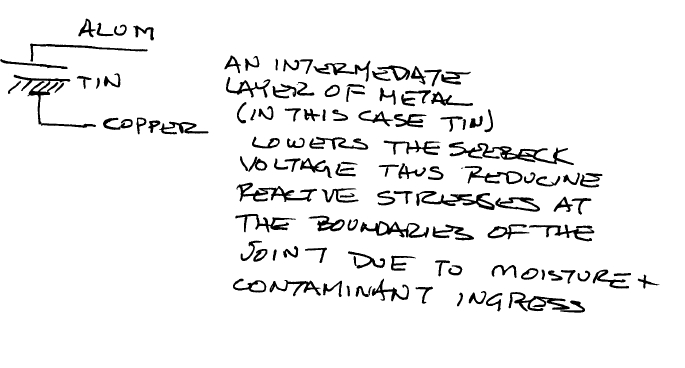

[img]cid:.1[/img]

Adding the layer of tin to the copper by plating insures

gas-tightness between the copper and tin but the mechanical

limitations of getting gas tightness between tin and aluminum

are unchanged . . . the advantage of this process is that the

Seebeck voltage developed between aluminum-tin thermocouple

is lower than aluminum-copper . . . hence the rate of corrosion

in the presence of dirty moisture is reduced. It's still not

zero but it is smaller. Virtually any, viscous, non-conductive

material in this space is an effective deterrent to the ingress

of dirty moisture.

For the most part, getting excited to action for the purpose

of preserving one's electrical joints has a poor return on

investment. I've never seen a callout on a production airplane

drawing for any form of guckem to be applied between electrical

parts before mating.

Cost of ownership risks are much greater for other members of

the family of attackers. I've seen devastating effects on the

tailcone of a nice ol' C-140 where colonies of mice took up

residence. That was the only airplane I ever thought about

buying and refurbishing . . . until I looked behind the

seats. Even the bulkhead flanges had big holes in them.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

78.33 KB |

| Viewed: |

13470 Time(s) |

|

| Description: |

|

| Filesize: |

87.58 KB |

| Viewed: |

13470 Time(s) |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Mon May 21, 2012 5:00 am Post subject: Re: Anti Corrosive Zinc Paste Posted: Mon May 21, 2012 5:00 am Post subject: Re: Anti Corrosive Zinc Paste |

|

|

I looked up Penetrox and there are several types; some for copper-to- copper, some for aluminum-to-copper or aluminum-to-aluminum.

Some history here is required: Years ago we experimented with materials that contained suspended copper or silver for the purpose of heat sinking large Xenon lamps, while simultaneously conducting current (>20A). Here what happened: KA-BLAM-O!!!

So we slinked back to using zinc oxide in silicone oil and no more problem. Why we thought suspended metal particles was a good idea is obvious...and wrong.

What happened was that the suspended metal particles conducted current while simultaneously preventing the really big flat contacts from mating. And the current you can conduct with thousands of microscopic particles is quite limited.

So: Using goop with suspended metal particles is probably a good idea at low current and modest voltage...like a connection to aluminum antennae, or Al-Cu pigtails in homes wired with aluminum. But it's probably a really bad idea with high currents at low voltages. Of course this depends on the size of the particles, the materials and hardness of the connectors and the pressure of the joint.

But I wouldn't use the metal-particle goop without thinking about it carefully.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

henador_titzoff(at)yahoo.

Guest

|

Posted: Mon May 21, 2012 3:08 pm Post subject: Anti Corrosive Zinc Paste Posted: Mon May 21, 2012 3:08 pm Post subject: Anti Corrosive Zinc Paste |

|

|

Thanks, Eric, I appreciate your analytic approach to our problems, with tests to determine validity.

Today I went to AutoZone and bought some Permatex Dielectric Grease in an 8 oz squeeze tube. It should last me for several years.

Also, today I saw three local electric utility guys get out of a Chevrolet souped up truck and start looking at one of their boxes. Two of them seemed to know what they were doing, while one was studying what I was doing, which was studying what they were doing. I walked across the street and asked them what they were doing, and he said that Engineering was looking at a switch box to see how it functioned. I asked him what it was switching, and he said 12,000V. I asked him how it got stepped down to 240V and 120V, and he said he didn't know. He asked one of the other guys, and they started looking around, finally spotting a box about two doors down. He said that box was a step down transformer. I asked him if he knew what Penetrox or No-Ox-ID was, and he said no and asked me what they were. I told him they were pastes with zinc used to coat aluminum wires to keep them from corroding, and he said he had heard of something like that. I'm not sure where they dug up this fossil, but for an electric utility engineer, he didn't know squat about his company's technology. I'm now guessing he was a mismanager.

Henador Titzoff

From: Eric M. Jones <emjones(at)charter.net>

To: aeroelectric-list(at)matronics.com

Sent: Monday, May 21, 2012 9:00 AM

Subject: Re: Anti Corrosive Zinc Paste

--> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net (emjones(at)charter.net)>

I looked up Penetrox and there are several types; some for copper-to- copper, some for aluminum-to-copper or aluminum-to-aluminum.

Some history here is required: Years ago we experimented with materials that contained suspended copper or silver for the purpose of heat sinking large Xenon lamps, while simultaneously conducting current (>20A). Here what happened: KA-BLAM-O!!!

So we slinked back to using zinc oxide in silicone oil and no more problem. Why we thought suspended metal particles was a good idea is obvious...and wrong.

What happened was that the suspended metal particles conducted current while simultaneously preventing the really big flat contacts from mating. And the current you can conduct with thousands of microscopic particles is quite limited.

So: Using goop with suspended metal particles is probably a good idea at low current and modest voltage...like a connection to aluminum antennae, or Al-Cu pigtails in homes wired with aluminum. But it's probably a really bad idea with high currents at low voltages. Of course this depends on the size of the particles, the materials and hardness of the connectors and the pressure of the joint.

But I wouldn't use the metal-particle goop without thinking about it carefully.

--------

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=373466#373466http://www.matronics.com/Navigator? - MATRONICS WEB FORUMS -<  ========================

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

millner(at)me.com

Guest

|

Posted: Tue May 22, 2012 10:19 pm Post subject: Anti Corrosive Zinc Paste Posted: Tue May 22, 2012 10:19 pm Post subject: Anti Corrosive Zinc Paste |

|

|

Unfortunately, utility hiring policies don't always select for the brightest bulbs, excusing the pun... which sometimes can be quite a challenge for their sophisticated customers who labor mightily, at times, to convince them that, for instance, current *still* equals voltage times resistance, or similar advanced concepts.

I once had to have days of meetings, and finally they had to fly their B+ student out from headquarters, to understand that it really was OK if we *gave* them a little power free from time to time to improve voltage regulation of their system in our neighborhood. Fortunately, he brightened (there's that pun again) and said, "Oh, I get it!" Revised contract language and relay settings were then only months of work process in coming.

It's kind of like government, though... the cynic says you want your best minds being entrepreneurial... not running the bureaucracies like Hitler and Mussolini did...

Paul

On 5/21/2012 4:06 PM, Henador Titzoff wrote: | Quote: | Thanks, Eric, I appreciate your analytic approach to our problems, with tests to determine validity.

Today I went to AutoZone and bought some Permatex Dielectric Grease in an 8 oz squeeze tube. It should last me for several years.

Also, today I saw three local electric utility guys get out of a Chevrolet souped up truck and start looking at one of their boxes. Two of them seemed to know what they were doing, while one was studying what I was doing, which was studying what they were doing. I walked across the street and asked them what they were doing, and he said that Engineering was looking at a switch box to see how it functioned. I asked him what it was switching, and he said 12,000V. I asked him how it got stepped down to 240V and 120V, and he said he didn't know. He asked one of the other guys, and they started looking around, finally spotting a box about two doors down. He said that box was a step down transformer. I asked him if he knew what Penetrox or No-Ox-ID was, and he said no and asked me what they were. I told him they were pastes with zinc used to coat aluminum wires to keep them from corroding, and he said he had heard of something like that. I'm not sure where they dug up this fossil, but for an electric utility engineer, he didn't know squat about his company's technology. I'm now guessing he was a mismanager.

Henador Titzoff

From: Eric M. Jones <emjones(at)charter.net> (emjones(at)charter.net)

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Sent: Monday, May 21, 2012 9:00 AM

Subject: Re: Anti Corrosive Zinc Paste

--> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net (emjones(at)charter.net)>

I looked up Penetrox and there are several types; some for copper-to- copper, some for aluminum-to-copper or aluminum-to-aluminum.

Some history here is required: Years ago we experimented with materials that contained suspended copper or silver for the purpose of heat sinking large Xenon lamps, while simultaneously conducting current (>20A). Here what happened: KA-BLAM-O!!!

So we slinked back to using zinc oxide in silicone oil and no more problem. Why we thought suspended metal particles was a good idea is obvious...and wrong.

What happened was that the suspended metal particles conducted current while simultaneously preventing the really big flat contacts from mating. And the current you can conduct with thousands of microscopic particles is quite limited.

So: Using goop with suspended metal particles is probably a good idea at low current and modest voltage...like a connection to aluminum antennae, or Al-Cu pigtails in homes wired with aluminum. But it's probably a really bad idea with high currents at low voltages. Of course this depends on the size of the particles, the materials and hardness of the connectors and the pressure of the joint.

But I wouldn't use the metal-particle goop without thinking about it carefully.

--------

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=373466#373466 http://www.matronics.com/Navigator? - MATRONICS WEB FORUMS -< ========================

--

Please note my new email address!

millner(at)me.com (millner(at)me.com) |

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

henador_titzoff(at)yahoo.

Guest

|

Posted: Wed May 23, 2012 3:29 am Post subject: Anti Corrosive Zinc Paste Posted: Wed May 23, 2012 3:29 am Post subject: Anti Corrosive Zinc Paste |

|

|

Paul,

I don't believe you're giving Hitler and Mussolini enough credit. If they were around today, no doubt they would be successful, big company retired CEOs. Hitler's resume would have had the following "bullets:"

- Implemented Sic Stigma

- Ran Germania Corporation for 12 years until successfully sold to United States in hostile takeover for billions of dollars

- Increased assets by annexing Polandia Corporation in a hostile takeover

- Milked Polandia Corporation out of all resources, then sold it to Russiatania Corporatioin for billions of dollars

- Plundered Romaniska Corporation in another hostile takeover to effectively utilize its oil reserves and other resources

- Annexed Franconia Corporation in order to increase world visibility and utilize resources to satisfy stockholders

- Generated multiple patents during tenure that are in use worldwide today

- Ordered HR to implement ethnic awareness and cleansing

- Successfully relocated problem employees to test labs and experiment stations

- Successfully shut down corporation during a hostile takeover by USA to satisfy stockholders and increase profits

- Created synergistic environment to allow smooth transition to new corporate management and bowed out gracefully

Henador Titzoff

From: Paul Millner <millner(at)me.com>

To: aeroelectric-list(at)matronics.com

Sent: Tuesday, May 22, 2012 3:52 PM

Subject: Re: Re: Anti Corrosive Zinc Paste

Unfortunately, utility hiring policies don't always select for the brightest bulbs, excusing the pun... which sometimes can be quite a challenge for their sophisticated customers who labor mightily, at times, to convince them that, for instance, current *still* equals voltage times resistance, or similar advanced concepts.

I once had to have days of meetings, and finally they had to fly their B+ student out from headquarters, to understand that it really was OK if we *gave* them a little power free from time to time to improve voltage regulation of their system in our neighborhood. Fortunately, he brightened (there's that pun again) and said, "Oh, I get it!" Revised contract language and relay settings were then only months of work process in coming.

It's kind of like government, though... the cynic says you want your best minds being entrepreneurial... not running the bureaucracies like Hitler and Mussolini did...

Paul

On 5/21/2012 4:06 PM, Henador Titzoff wrote: [quote] Thanks, Eric, I appreciate your analytic approach to our problems, with tests to determine validity.

Today I went to AutoZone and bought some Permatex Dielectric Grease in an 8 oz squeeze tube. It should last me for several years.

Also, today I saw three local electric utility guys get out of a Chevrolet souped up truck and start looking at one of their boxes. Two of them seemed to know what they were doing, while one was studying what I was doing, which was studying what they were doing. I walked across the street and asked them what they were doing, and he said that Engineering was looking at a switch box to see how it functioned. I asked him what it was switching, and he said 12,000V. I asked him how it got stepped down to 240V and 120V, and he said he didn't know. He asked one of the other guys, and they started looking around, finally spotting a box about two doors down. He said that box was a step down transformer. I asked him if he knew what Penetrox or No-Ox-ID was, and he said no and asked me what they were. I told him they were pastes with zinc used to coat aluminum wires to keep them from corroding, and he said he had heard of something like that. I'm not sure where they dug up this fossil, but for an electric utility engineer, he didn't know squat about his company's technology. I'm now guessing he was a mismanager.

Henador Titzoff

From: Eric M. Jones <emjones(at)charter.net> (emjones(at)charter.net)

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Sent: Monday, May 21, 2012 9:00 AM

Subject: AeroElectric-List: Re: Anti Corrosive Zinc Paste

--> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net (emjones(at)charter.net)>

I looked up Penetrox and there are several types; some for copper-to- copper, some for aluminum-to-copper or aluminum-to-aluminum.

Some history here is required: Years ago we experimented with materials that contained suspended copper or silver for the purpose of heat sinking large Xenon lamps, while simultaneously conducting current (>20A). Here what happened: KA-BLAM-O!!!

So we slinked back to using zinc oxide in silicone oil and no more problem. Why we thought suspended metal particles was a good idea is obvious...and wrong.

What happened was that the suspended metal particles conducted current while simultaneously preventing the really big flat contacts from mating. And the current you can conduct with thousands of microscopic particles is quite limited.

So: Using goop with suspended metal particles is probably a good idea at low current and modest voltage...like a connection to aluminum antennae, or Al-Cu pigtails in homes wired with aluminum. But it's probably a really bad idea with high currents at low voltages. Of course this depends on the size of the particles, the materials and hardness of the connectors and the pressure of the joint.

But I wouldn't use the metal-particle goop without thinking about it carefully.

--------

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=373466#373466 http://www.matronics.com/Navigator? - MATRONICS WEB FORUMS -< ========================

--

Please note my new email address!

millner(at)me.com (millner(at)me.com)[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

email(at)jaredyates.com

Guest

|

Posted: Wed May 23, 2012 4:18 am Post subject: Anti Corrosive Zinc Paste Posted: Wed May 23, 2012 4:18 am Post subject: Anti Corrosive Zinc Paste |

|

|

The other day I was communicating with an airplane builder about electrical systems in an online venue other than this one. His ideas weren't consistent with what I've come to understand as best practices, so I suggested that he join the AEC list. His response was "the last thing I need is that many email messages in my inbox every day." I thought it was such a shame that he felt that way, and that in some sense, his safety of flight would be jeopardized for reasons that amount to nothing more than logistics. Is it his own fault because he didn't want to just delete the unrelated messages? Is it the fault of the list moderators for not running a tighter ship? I'm sure that those are both factors, but neither is entirely responsible. Certainly there are many discussions that stray from the electrical system topics that are still useful and educational (with the recent paste discussion being one of many). Is it possible to have a list that stays on topic, but still keeps the benefits of group interaction and crowd-sourcing? I don't know, but I do know that I've seen online communities grow strong, fail, and even be brought back from the brink. The most prominent common feature that I see among failed or failing groups is a lack of civility, and respect among members. That usually starts with author anonymity, which thankfully we don't typically have here. It usually continues with off-topic discussions that are contentious, as political discussions always are. It seems inevitable that one side or the other usually starts to make more noise, and the folks on the other side gradually leave until all that's left is an echo chamber of like-minded folks who keep coming back just so that they can be around people who agree with them. I sure hope that this list isn't going to go down a path that leads to this kind of end. I don't think that we're anywhere close to that state yet, and that's why I bring it up- this is how it starts, and like many other infectious patterns, early intervention is certainly the most effort-effective solution. So as list members, what are we going to do? Are we going to each take individual responsibility to keep the group on topic? Are we going to let the list become what it may, for better or worse, just so that we can get our points across? I'd like to vote for option 1, and encourage others to do the same. I don't know which is better or which will prevail. But I do know that I have enough faith in Bob's work to bet my life on it, and I'd certainly like to have a place where I can stay abreast of changes and updates to the system designs, and the gradual changes to what we think of as best practices. Wouldn't it be great if this list can continue to be that source? Isn't that more likely to be the case if we can stay away from these kinds of discussions, whether or not we agree with the points?

On May 23, 2012, at 7:22, Henador Titzoff <henador_titzoff(at)yahoo.com (henador_titzoff(at)yahoo.com)> wrote:

[quote] Paul,

I don't believe you're giving Hitler and Mussolini enough credit. If they were around today, no doubt they would be successful, big company retired CEOs. Hitler's resume would have had the following "bullets:"

- Implemented Sic Stigma

- Ran Germania Corporation for 12 years until successfully sold to United States in hostile takeover for billions of dollars

- Increased assets by annexing Polandia Corporation in a hostile takeover

- Milked Polandia Corporation out of all resources, then sold it to Russiatania Corporatioin for billions of dollars

- Plundered Romaniska Corporation in another hostile takeover to effectively utilize its oil reserves and other resources

- Annexed Franconia Corporation in order to increase world visibility and utilize resources to satisfy stockholders

- Generated multiple patents during tenure that are in use worldwide today

- Ordered HR to implement ethnic awareness and cleansing

- Successfully relocated problem employees to test labs and experiment stations

- Successfully shut down corporation during a hostile takeover by USA to satisfy stockholders and increase profits

- Created synergistic environment to allow smooth transition to new corporate management and bowed out gracefully

Henador Titzoff

From: Paul Millner <millner(at)me.com (millner(at)me.com)>

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Sent: Tuesday, May 22, 2012 3:52 PM

Subject: Re: Re: Anti Corrosive Zinc Paste

Unfortunately, utility hiring policies don't always select for the brightest bulbs, excusing the pun... which sometimes can be quite a challenge for their sophisticated customers who labor mightily, at times, to convince them that, for instance, current *still* equals voltage times resistance, or similar advanced concepts.

I once had to have days of meetings, and finally they had to fly their B+ student out from headquarters, to understand that it really was OK if we *gave* them a little power free from time to time to improve voltage regulation of their system in our neighborhood. Fortunately, he brightened (there's that pun again) and said, "Oh, I get it!" Revised contract language and relay settings were then only months of work process in coming.

It's kind of like government, though... the cynic says you want your best minds being entrepreneurial... not running the bureaucracies like Hitler and Mussolini did...

Paul

On 5/21/2012 4:06 PM, Henador Titzoff wrote: | Quote: | Thanks, Eric, I appreciate your analytic approach to our problems, with tests to determine validity.

Today I went to AutoZone and bought some Permatex Dielectric Grease in an 8 oz squeeze tube. It should last me for several years.

Also, today I saw three local electric utility guys get out of a Chevrolet souped up truck and start looking at one of their boxes. Two of them seemed to know what they were doing, while one was studying what I was doing, which was studying what they were doing. I walked across the street and asked them what they were doing, and he said that Engineering was looking at a switch box to see how it functioned. I asked him what it was switching, and he said 12,000V. I asked him how it got stepped down to 240V and 120V, and he said he didn't know. He asked one of the other guys, and they started looking around, finally spotting a box about two doors down. He said that box was a step down transformer. I asked him if he knew what Penetrox or No-Ox-ID was, and he said no and asked me what they were. I told him they were pastes with zinc used to coat aluminum wires to keep them from corroding, and he said he had heard of something like that. I'm not sure where they dug up this fossil, but for an electric utility engineer, he didn't know squat about his company's technology. I'm now guessing he was a mismanager.

Henador Titzoff

From: Eric M. Jones <emjones(at)charter.net> (emjones(at)charter.net)

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Sent: Monday, May 21, 2012 9:00 AM

Subject: Re: Anti Corrosive Zinc Paste

--> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net (emjones(at)charter.net)>

I looked up Penetrox and there are several types; some for copper-to- copper, some for aluminum-to-copper or aluminum-to-aluminum.

Some history here is required: Years ago we experimented with materials that contained suspended copper or silver for the purpose of heat sinking large Xenon lamps, while simultaneously conducting current (>20A). Here what happened: KA-BLAM-O!!!

So we slinked back to using zinc oxide in silicone oil and no more problem. Why we thought suspended metal particles was a good idea is obvious...and wrong.

What happened was that the suspended metal particles conducted current while simultaneously preventing the really big flat contacts from mating. And the current you can conduct with thousands of microscopic particles is quite limited.

So: Using goop with suspended metal particles is probably a good idea at low current and modest voltage...like a connection to aluminum antennae, or Al-Cu pigtails in homes wired with aluminum. But it's probably a really bad idea with high currents at low voltages. Of course this depends on the size of the particles, the materials and hardness of the connectors and the pressure of the joint.

But I wouldn't use the metal-particle goop without thinking about it carefully.

--------

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

[url=tel:%28508%29%20764-2072](508) 764-2072[/url]

emjones(at)charter.net

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=373466#373466 http://www.matronics.com/Navigator? - MATRONICS WEB FORUMS -< ========================

--

Please note my new email address!

millner(at)me.com (millner(at)me.com)

ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

tp://forums.matronics.com

_blank">http://www.matronics.com/contribution

|

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

henador_titzoff(at)yahoo.

Guest

|

Posted: Wed May 23, 2012 4:59 am Post subject: Anti Corrosive Zinc Paste Posted: Wed May 23, 2012 4:59 am Post subject: Anti Corrosive Zinc Paste |

|

|

I agree with you wholeheartedly, Jared. I apologize for posting the message below. Let's get back on topic.

Henador Titzoff

From: Jared Yates <email(at)jaredyates.com>

To: "aeroelectric-list(at)matronics.com" <aeroelectric-list(at)matronics.com>

Sent: Wednesday, May 23, 2012 8:13 AM

Subject: Re: AeroElectric-List: Re: Anti Corrosive Zinc Paste

The other day I was communicating with an airplane builder about electrical systems in an online venue other than this one. His ideas weren't consistent with what I've come to understand as best practices, so I suggested that he join the AEC list. His response was "the last thing I need is that many email messages in my inbox every day." I thought it was such a shame that he felt that way, and that in some sense, his safety of flight would be jeopardized for reasons that amount to nothing more than logistics. Is it his own fault because he didn't want to just delete the unrelated messages? Is it the fault of the list moderators for not running a tighter ship? I'm sure that those are both factors, but neither is entirely responsible. Certainly there are many discussions that stray from the electrical system topics that are still useful and educational (with the recent paste discussion being one of many). Is it possible to have a list that stays on topic, but still keeps the benefits of group interaction and crowd-sourcing? I don't know, but I do know that I've seen online communities grow strong, fail, and even be brought back from the brink. The most prominent common feature that I see among failed or failing groups is a lack of civility, and respect among members. That usually starts with author anonymity, which thankfully we don't typically have here. It usually continues with off-topic discussions that are contentious, as political discussions always are. It seems inevitable that one side or the other usually starts to make more noise, and the folks on the other side gradually leave until all that's left is an echo chamber of like-minded folks who keep coming back just so that they can be around people who agree with them. I sure hope that this list isn't going to go down a path that leads to this kind of end. I don't think that we're anywhere close to that state yet, and that's why I bring it up- this is how it starts, and like many other infectious patterns, early intervention is certainly the most effort-effective solution. So as list members, what are we going to do? Are we going to each take individual responsibility to keep the group on topic? Are we going to let the list become what it may, for better or worse, just so that we can get our points across? I'd like to vote for option 1, and encourage others to do the same. I don't know which is better or which will prevail. But I do know that I have enough faith in Bob's work to bet my life on it, and I'd certainly like to have a place where I can stay abreast of changes and updates to the system designs, and the gradual changes to what we think of as best practices. Wouldn't it be great if this list can continue to be that source? Isn't that more likely to be the case if we can stay away from these kinds of discussions, whether or not we agree with the points?

On May 23, 2012, at 7:22, Henador Titzoff <henador_titzoff(at)yahoo.com (henador_titzoff(at)yahoo.com)> wrote:

[quote] Paul,

I don't believe you're giving Hitler and Mussolini enough credit. If they were around today, no doubt they would be successful, big company retired CEOs. Hitler's resume would have had the following "bullets:"

- Implemented Sic Stigma

- Ran Germania Corporation for 12 years until successfully sold to United States in hostile takeover for billions of dollars

- Increased assets by annexing Polandia Corporation in a hostile takeover

- Milked Polandia Corporation out of all resources, then sold it to Russiatania Corporatioin for billions of dollars

- Plundered Romaniska Corporation in another hostile takeover to effectively utilize its oil reserves and other resources

- Annexed Franconia Corporation in order to increase world visibility and utilize resources to satisfy stockholders

- Generated multiple patents during tenure that are in use worldwide today

- Ordered HR to implement ethnic awareness and cleansing

- Successfully relocated problem employees to test labs and experiment stations

- Successfully shut down corporation during a hostile takeover by USA to satisfy stockholders and increase profits

- Created synergistic environment to allow smooth transition to new corporate management and bowed out gracefully

Henador Titzoff

From: Paul Millner <millner(at)me.com (millner(at)me.com)>

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Sent: Tuesday, May 22, 2012 3:52 PM

Subject: Re: Re: Anti Corrosive Zinc Paste

Unfortunately, utility hiring policies don't always select for the brightest bulbs, excusing the pun... which sometimes can be quite a challenge for their sophisticated customers who labor mightily, at times, to convince them that, for instance, current *still* equals voltage times resistance, or similar advanced concepts.

I once had to have days of meetings, and finally they had to fly their B+ student out from headquarters, to understand that it really was OK if we *gave* them a little power free from time to time to improve voltage regulation of their system in our neighborhood. Fortunately, he brightened (there's that pun again) and said, "Oh, I get it!" Revised contract language and relay settings were then only months of work process in coming.

It's kind of like government, though... the cynic says you want your best minds being entrepreneurial... not running the bureaucracies like Hitler and Mussolini did...

Paul

On 5/21/2012 4:06 PM, Henador Titzoff wrote: | Quote: | Thanks, Eric, I appreciate your analytic approach to our problems, with tests to determine validity.

Today I went to AutoZone and bought some Permatex Dielectric Grease in an 8 oz squeeze tube. It should last me for several years.

Also, today I saw three local electric utility guys get out of a Chevrolet souped up truck and start looking at one of their boxes. Two of them seemed to know what they were doing, while one was studying what I was doing, which was studying what they were doing. I walked across the street and asked them what they were doing, and he said that Engineering was looking at a switch box to see how it functioned. I asked him what it was switching, and he said 12,000V. I asked him how it got stepped down to 240V and 120V, and he said he didn't know. He asked one of the other guys, and they started looking around, finally spotting a box about two doors down. He said that box was a step down transformer. I asked him if he knew what Penetrox or No-Ox-ID was, and he said no and asked me what they were. I told him they were pastes with zinc used to coat aluminum wires to keep them from corroding, and he said he had heard of something like that. I'm not sure where they dug up this fossil, but for an electric utility engineer, he didn't know squat about his company's technology. I'm now guessing he was a mismanager.

Henador Titzoff

From: Eric M. Jones <emjones(at)charter.net> (emjones(at)charter.net)

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Sent: Monday, May 21, 2012 9:00 AM

Subject: Re: Anti Corrosive Zinc Paste

--> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net (emjones(at)charter.net)>

I looked up Penetrox and there are several types; some for copper-to- copper, some for aluminum-to-copper or aluminum-to-aluminum.

Some history here is required: Years ago we experimented with materials that contained suspended copper or silver for the purpose of heat sinking large Xenon lamps, while simultaneously conducting current (>20A). Here what happened: KA-BLAM-O!!!

So we slinked back to using zinc oxide in silicone oil and no more problem. Why we thought suspended metal particles was a good idea is obvious...and wrong.

What happened was that the suspended metal particles conducted current while simultaneously preventing the really big flat contacts from mating. And the current you can conduct with thousands of microscopic particles is quite limited.

So: Using goop with suspended metal particles is probably a good idea at low current and modest voltage...like a connection to aluminum antennae, or Al-Cu pigtails in homes wired with aluminum. But it's probably a really bad idea with high currents at low voltages. Of course this depends on the size of the particles, the materials and hardness of the connectors and the pressure of the joint.

But I wouldn't use the metal-particle goop without thinking about it carefully.

--------

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=373466#373466 http://www.matronics.com/Navigator? - MATRONICS WEB FORUMS -< ========================

--

Please note my new email address!

millner(at)me.com (millner(at)me.com)

ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

tp://forums.matronics.com

_blank">http://www.matronics.com/contribution

|

http://www.matro====================

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jay(at)horriblehyde.com

Guest

|

Posted: Wed May 23, 2012 10:19 am Post subject: Anti Corrosive Zinc Paste Posted: Wed May 23, 2012 10:19 am Post subject: Anti Corrosive Zinc Paste |

|

|

J Most bright people are too busy inventing the next amazing thing to worry about how the present amazing thing is being applied/ installed/ used.

I recently gave a birthday speech in which I noted that what one certainly does NOT want in life is mediocrity, and that, considering my friends, I could observe a paucity of mediocrity. I am most pleased to say that this is the same on the aeroelectric list!

Jay

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Paul Millner

Sent: 22 May 2012 09:52 PM

To: aeroelectric-list(at)matronics.com

Subject: Re: Re: Anti Corrosive Zinc Paste

Unfortunately, utility hiring policies don't always select for the brightest bulbs, excusing the pun... which sometimes can be quite a challenge for their sophisticated customers who labor mightily, at times, to convince them that, for instance, current *still* equals voltage times resistance, or similar advanced concepts.

I once had to have days of meetings, and finally they had to fly their B+ student out from headquarters, to understand that it really was OK if we *gave* them a little power free from time to time to improve voltage regulation of their system in our neighborhood. Fortunately, he brightened (there's that pun again) and said, "Oh, I get it!" Revised contract language and relay settings were then only months of work process in coming.

It's kind of like government, though... the cynic says you want your best minds being entrepreneurial... not running the bureaucracies like Hitler and Mussolini did...

Paul

On 5/21/2012 4:06 PM, Henador Titzoff wrote:

Thanks, Eric, I appreciate your analytic approach to our problems, with tests to determine validity.

Today I went to AutoZone and bought some Permatex Dielectric Grease in an 8 oz squeeze tube. It should last me for several years.

Also, today I saw three local electric utility guys get out of a Chevrolet souped up truck and start looking at one of their boxes. Two of them seemed to know what they were doing, while one was studying what I was doing, which was studying what they were doing. I walked across the street and asked them what they were doing, and he said that Engineering was looking at a switch box to see how it functioned. I asked him what it was switching, and he said 12,000V. I asked him how it got stepped down to 240V and 120V, and he said he didn't know. He asked one of the other guys, and they started looking around, finally spotting a box about two doors down. He said that box was a step down transformer. I asked him if he knew what Penetrox or No-Ox-ID was, and he said no and asked me what they were. I told him they were pastes with zinc used to coat aluminum wires to keep them from corroding, and he said he had heard of something like that. I'm not sure where they dug up this fossil, but for an electric utility engineer, he didn't know squat about his company's technology. I'm now guessing he was a mismanager.

Henador Titzoff

From: Eric M. Jones <emjones(at)charter.net> (emjones(at)charter.net)

To: aeroelectric-list(at)matronics.com (aeroelectric-list(at)matronics.com)

Sent: Monday, May 21, 2012 9:00 AM

Subject: Re: Anti Corrosive Zinc Paste

--> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net (emjones(at)charter.net)>

I looked up Penetrox and there are several types; some for copper-to- copper, some for aluminum-to-copper or aluminum-to-aluminum.

Some history here is required: Years ago we experimented with materials that contained suspended copper or silver for the purpose of heat sinking large Xenon lamps, while simultaneously conducting current (>20A). Here what happened: KA-BLAM-O!!!

So we slinked back to using zinc oxide in silicone oil and no more problem. Why we thought suspended metal particles was a good idea is obvious...and wrong.

What happened was that the suspended metal particles conducted current while simultaneously preventing the really big flat contacts from mating. And the current you can conduct with thousands of microscopic particles is quite limited.

So: Using goop with suspended metal particles is probably a good idea at low current and modest voltage...like a connection to aluminum antennae, or Al-Cu pigtails in homes wired with aluminum. But it's probably a really bad idea with high currents at low voltages. Of course this depends on the size of the particles, the materials and hardness of the connectors and the pressure of the joint.

But I wouldn't use the metal-particle goop without thinking about it carefully.

--------

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=373466#373466 http://www.matronics.com/Navigator? - MATRONICS WEB FORUMS -< ========================

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|