|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

donjohnston

Joined: 13 Dec 2009

Posts: 232

|

Posted: Sun Jul 28, 2013 6:09 am Post subject: Multi-hop wire sizing? Posted: Sun Jul 28, 2013 6:09 am Post subject: Multi-hop wire sizing? |

|

|

When sizing wires, do you use the total distance or segment distance?

For example: The starter is a total of 15' from the battery. But that total distance is made up of a 1' battery-to-master contactor, 12' master contactor-to-starter contactor and 4' starter contactor-to-starter.

So do we use a 30' round trip distance when sizing all the wires? Or do we size each segment based on its distance (i.e. 8' for the starter contactor to starter)?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jul 28, 2013 8:18 am Post subject: Multi-hop wire sizing? Posted: Sun Jul 28, 2013 8:18 am Post subject: Multi-hop wire sizing? |

|

|

At 09:09 AM 7/28/2013, you wrote:

| Quote: |

When sizing wires, do you use the total distance or segment distance?

For example: The starter is a total of 15' from the battery. But

that total distance is made up of a 1' battery-to-master contactor,

12' master contactor-to-starter contactor and 4' starter contactor-to-starter.

So do we use a 30' round trip distance when sizing all the wires? Or

do we size each segment based on its distance (i.e. 8' for the

starter contactor to starter)?

|

Voltage drop calculations for the cranking

scenario are not particularly satisfying.

What size engine . . . are you considering a PM

starter? Do you anticipate cold weather operations?

Your words paint an image of a plastic, canard pusher

with battery in the nose. 95+ percent do just fine

with 2AWG wire which will have more than the 'idealized'

5% voltage drop for continuous duty ops of appliances

but acceptable for the few seconds it takes to get

an engine running.

Put starter contactor on firewall and use cranking

feeder to bring alternator b-lead forward.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

donjohnston

Joined: 13 Dec 2009

Posts: 232

|

Posted: Sun Jul 28, 2013 2:10 pm Post subject: Re: Multi-hop wire sizing? Posted: Sun Jul 28, 2013 2:10 pm Post subject: Re: Multi-hop wire sizing? |

|

|

Correct. Velocity with the battery (24v) in the nose and the starter contactor on the firewall. Continental IO-550N with a factory starter. I can't find the specs on the starter but I've been told that 200a is a conservative starting point.

So for instance, the length from the starter contactor to the starter is 4'. Based on the chart in 43.13 (which requires some extrapolation for a 200a load), theoretically, I could get by with 8AWG for that run. Whereas the master to starter contactor would require 4AWG.

Which brings me back all the way back around to the question of: Is the wire size based on the total distance or per segment distance?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

wrmaxwell(at)bigpond.com

Guest

|

Posted: Sun Jul 28, 2013 2:25 pm Post subject: Multi-hop wire sizing? Posted: Sun Jul 28, 2013 2:25 pm Post subject: Multi-hop wire sizing? |

|

|

I would add to Bob's response that in any circuit, you need to ensure that the conductors involved, be they wire or bus metal, are adequately sized to carry the required current from source, the battery, to the load, the starter in your example, and back, as the current always has to take that round trip.

Bill

On 29/07/2013 12:09 AM, donjohnston wrote:

[quote] | Quote: | --> AeroElectric-List message posted by: "donjohnston" <don(at)velocity-xl.com> (don(at)velocity-xl.com)

When sizing wires, do you use the total distance or segment distance?

For example: The starter is a total of 15' from the battery. But that total distance is made up of a 1' battery-to-master contactor, 12' master contactor-to-starter contactor and 4' starter contactor-to-starter.

So do we use a 30' round trip distance when sizing all the wires? Or do we size each segment based on its distance (i.e. 8' for the starter contactor to starter)?

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=405493#405493

|

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jul 28, 2013 3:39 pm Post subject: Multi-hop wire sizing? Posted: Sun Jul 28, 2013 3:39 pm Post subject: Multi-hop wire sizing? |

|

|

| Quote: | >So do we use a 30' round trip distance when sizing all the wires?

>Or do we size each segment based on its distance (i.e. 8' for the

>starter contactor to starter)?

|

Neither. As I tried to articulate earlier, selection of wire

in the cranking circuit is not driven by current rating

of wire based on temperature rise and only loosely based

on voltage drop.

In the TC aircraft world, we concern ourselves with worst

case situations like battery nearing end of life, engine

and battery are cold-soaked at the lowest operating temperatures

recommended by engineering and marketing for operations

without ground assist (pre-heat or ground power cart).

There are lots of warm weather VariEz drivers who did their

long runs with 4AWG . . . and I've not heard of anyone finding it

useful to change out the wire . . . more than likely

they would go for a more robust battery first.

200A at 18 volts (worst case battery volts for starting)

is about half again more energy than the 300A at 9v

we use as a rule-of-thumb for 14 volt airplanes.

But I can tell you that nobody I've ever known picked

a cranking system wire size based on any predictive

performance based on analysis or calculation. I know

of some airplanes (a noteworthy Piper Cherokee) that

got a 'heavy duty' battery option added to its type

certificate due to poor cranking performance complaints

by some customers. These customers found it more attractive

to upsize to a 35 a.h. battery than to change out the

starter or make any other changes to reduce the stack-up

of conditions that degraded cranking.

If you're going to limit to warm weather flying and

plan to keep the battery well maintained, then perhaps

4AWG will be adequate to your intended use of the

airplane. 2AWG wire was common to all small SE aircraft

with remote mounted batteries. Once the batteries

moved forward to the firewall, I think the shift to

4AWG was axiomatic.

Selection of wire in this case was more a matter of

sticking a wet finger (or soggy battery) into a -20C

breeze than any carefully calculated design decision.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

donjohnston

Joined: 13 Dec 2009

Posts: 232

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jul 29, 2013 9:09 am Post subject: Multi-hop wire sizing? Posted: Mon Jul 29, 2013 9:09 am Post subject: Multi-hop wire sizing? |

|

|

At 11:15 AM 7/29/2013, you wrote:

| Quote: |

Thanks for the reply.

But I still am unclear on something.

Let me try a different example.

The alternator (50a) B lead will connect to the battery side of the

starter contactor on the firewall. That wire will be about 4' long.

When I size that wire, do I only consider the 4' distance and ignore

the larger wire to the battery? (In which the alternator wire can be 12AWG)

|

Yes, that wire is not part of the cranking system

and is rated for continuous duty operation at some

current level and ambient temperature.

So the alternator b-lead is sized to the alternator's

output. Don't know where you got 12AWG . . . 6 AWG

is closer to appropriate.

| Quote: | Or do I consider the length from the alternator to the battery. (In

which case I'm looking at 8AWG).

|

???? distance is not a factor here on these short runs.

It's temperature rise over ambient when subjected

to the design currents.

| Quote: | Sorry if I'm not making my question clear. [Embarassed]

|

I'm sorry I didn't pick up on your concerns. We're

getting wrapped around the axles of minute details

that most venues have put aside with conservative

selection as opposed to spending $time$ on slicing

and dicing the options. I'd go to local weld shop

where I know you can get 4AWG welding cable . . .

and put a hunk of that nice flexible stuff in for

a b-lead feeder. If they stock 6AWG, cool, use

that.

But once that wire ties into the battery/starter

feeders for cranking, all the slicing and dicing for continuous

duty service is replaced with meeting design goals.

Goals in intermittent duty service where supply

voltage, load current and energy demands levied

by engine characteristics and pilot skills

stack up to suggest much fatter wires.

Wires so fat as to be insignificant

players in the voltage drop issues for the

continuous duty studies driven by a load

analysis.

If it were my airplane with 30' of cranking

loop, I'd go with 2AWG. B-lead at 4AWG. If

you've got a hydraulic gear pump, then you

MIGHT drop to 6AWG for that feeder but if

it is short and 4AWG was all the local shop

had in stock, make that 4AWG too.

The problems your wrestling with have legacy

solutions borne more of field experience and

practice than of finely tuned analysis.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

donjohnston

Joined: 13 Dec 2009

Posts: 232

|

Posted: Mon Jul 29, 2013 9:28 am Post subject: Re: Multi-hop wire sizing? Posted: Mon Jul 29, 2013 9:28 am Post subject: Re: Multi-hop wire sizing? |

|

|

| Quote: |

Yes, that wire is not part of the cranking system

and is rated for continuous duty operation at some

current level and ambient temperature. |

Thanks! That's what I was looking for.

| Quote: |

So the alternator b-lead is sized to the alternator's

output. Don't know where you got 12AWG . . . 6 AWG

is closer to appropriate. |

The chart in AC43-13 indicates that 28v over ~10' at 50a works out to 12AWG.

I've got some pretty tight ducts for wire and I'm trying to conserve space as much as possible and at the same time meet the electron moving requirements.

The hydraulic pump is only about 18" from the battery and draws ~25a. So I'm thinking of running 14AWG there.

Thanks again,

Don

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

billp(at)wwpc.com

Guest

|

Posted: Mon Jul 29, 2013 9:34 am Post subject: Multi-hop wire sizing? Posted: Mon Jul 29, 2013 9:34 am Post subject: Multi-hop wire sizing? |

|

|

So...

1) I'd say that a 12 AWG wire is a little on the light side for 50A.

Should be a 6 or 8 AWG according to AC 43.13-1B.

b) I would recommend a 50A circuit breaker (push-pull or toggle) between

the alternator and the battery side of the starter relay that can be

operated by the pilot. It's bad when an alternator dies (open) and

doesn't charge when in flight. It's much worse when an alternator dies

(shorted) and starts draining the battery as fast as it can. In my

airplane, their is a wire from the battery side of the starter solenoid

to the master bus (where all the circuit breakers are) and the

alternator is just another one on that bus. Of course there is also a 5A

breaker for the "field" (really goes to the regulator and then to the

rotor in the alternator).

III) In all cases you first look at AC 43.13-1B

(http://www.faa.gov/regulations_policies/advisory_circulars/index.cfm/go/document.information/documentid/99861)

Table 11-9 to find the minimum size wire you need. This is the wire's

maximum capacity regardless of length. It is based on the heat generated

as the current flows though the wire's internal resistance (you know

current * resistance per foot = watts of heat per foot). Select the wire

the size dictated by the load and wire temperature rating. For a 50A

circuit you need an 8 or 6 AWG wire depending on the temperature rating.

Then, use AC 43.13-1B Figure 11-3 to determine the larger size wire

needed if a longer wire run would have too much voltage drop for the

circuit. Length is the round trip circuit so if you're using the

airframe in a well bonded aluminum airplane the ground return is pretty

much ignored. If you've got a nav light at the tip of a fiberglass wing,

you have to calculate the length including the hot wire out to the load

and the ground return wire length back.

Note to self: I really have to connect the engine to the airframe (or

ground bus in a composite aircraft) with at least as big a wire as I

used for the starter. Bolts through the engine shock mounts don't count.

Bill

On 7/29/13 9:15 AM, donjohnston wrote:

| Quote: |

Thanks for the reply.

But I still am unclear on something.

Let me try a different example.

The alternator (50a) B lead will connect to the battery side of the starter contactor on the firewall. That wire will be about 4' long. When I size that wire, do I only consider the 4' distance and ignore the larger wire to the battery? (In which the alternator wire can be 12AWG)

Or do I consider the length from the alternator to the battery. (In which case I'm looking at 8AWG).

Sorry if I'm not making my question clear. [Embarassed]

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=405574#405574

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

donjohnston

Joined: 13 Dec 2009

Posts: 232

|

Posted: Mon Jul 29, 2013 12:32 pm Post subject: Re: Multi-hop wire sizing? Posted: Mon Jul 29, 2013 12:32 pm Post subject: Re: Multi-hop wire sizing? |

|

|

| Quote: | 1) I'd say that a 12 AWG wire is a little on the light side for 50A.

Should be a 6 or 8 AWG according to AC 43.13-1B. |

My interpretation of figure 11-2 from 43-13-1B shows 12AWG. Are you sure you're looking at the 28v column?

| Quote: | b) I would recommend a 50A circuit breaker (push-pull or toggle) between the alternator and the battery side of the starter relay that can be

operated by the pilot. It's bad when an alternator dies (open) and

doesn't charge when in flight. It's much worse when an alternator dies

(shorted) and starts draining the battery as fast as it can. In my

airplane, their is a wire from the battery side of the starter solenoid

to the master bus (where all the circuit breakers are) and the

alternator is just another one on that bus. Of course there is also a 5A

breaker for the "field" (really goes to the regulator and then to the

rotor in the alternator).

|

Excellent point. But with that configuration, it doesn't make sense to put the starter contactor on the firewall because I'll still need to run the alternator wire all the way up to the front anyway. I was planning on an ANL50 for protection.

| Quote: | III) In all cases you first look at AC 43.13-1B

(http://www.faa.gov/regulations_policies/advisory_circulars/index.cfm/go/document.information/documentid/99861)

Table 11-9 to find the minimum size wire you need. This is the wire's

maximum capacity regardless of length. It is based on the heat generated

as the current flows though the wire's internal resistance (you know

current * resistance per foot = watts of heat per foot). Select the wire

the size dictated by the load and wire temperature rating. For a 50A

circuit you need an 8 or 6 AWG wire depending on the temperature rating. |

I'll look into that.

| Quote: | Then, use AC 43.13-1B Figure 11-3 to determine the larger size wire

needed if a longer wire run would have too much voltage drop for the

circuit. Length is the round trip circuit so if you're using the

airframe in a well bonded aluminum airplane the ground return is pretty

much ignored. If you've got a nav light at the tip of a fiberglass wing,

you have to calculate the length including the hot wire out to the load

and the ground return wire length back. |

Figure 11-3 in my copy is for intermittent load.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jul 29, 2013 1:20 pm Post subject: Multi-hop wire sizing? Posted: Mon Jul 29, 2013 1:20 pm Post subject: Multi-hop wire sizing? |

|

|

At 12:33 PM 7/29/2013, you wrote:

| Quote: | --> AeroElectric-List message posted by: Bill Putney <billp(at)wwpc.com>

So...

1) I'd say that a 12 AWG wire is a little on the light side for 50A. Should be a 6 or 8 AWG according to AC 43.13-1B.

b) I would recommend a 50A circuit breaker (push-pull or toggle) between the alternator and the battery side of the starter relay that can be operated by the pilot. |

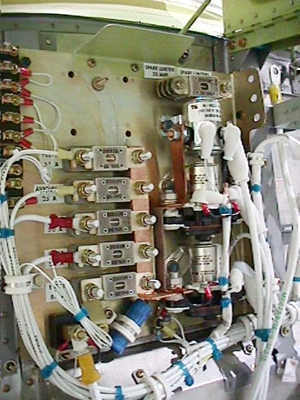

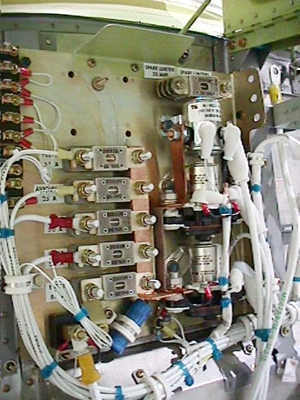

Crew accessible b-lead breakers have pretty much gone

the way of the ADF and LORAN receivers.

B-lead protection moved out to the firewall on Bonanzas

about 35-30 years ago.

[img]cid:7.1.0.9.0.20130729161236.020c35c0(at)aeroelectric.com.0[/img]

Not sure what the philosophy is for current

single engine production. I'll have to see

if I still know anyone at Cessna or Piper.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

127.54 KB |

| Viewed: |

11343 Time(s) |

|

|

|

| Back to top |

|

|

billp(at)wwpc.com

Guest

|

Posted: Mon Jul 29, 2013 4:06 pm Post subject: Multi-hop wire sizing? Posted: Mon Jul 29, 2013 4:06 pm Post subject: Multi-hop wire sizing? |

|

|

On 7/29/13 1:32 PM, donjohnston wrote:

| Quote: |

> 1) I'd say that a 12 AWG wire is a little on the light side for 50A.

> Should be a 6 or 8 AWG according to AC 43.13-1B.

My interpretation of figure 11-2 from 43-13-1B shows 12AWG. Are you sure you're looking at the 28v column?

In that table voltage is irrelevant. It's the maximum current a wire of

|

a selected gauge (based on the internal resistance of the wire and the

amount of heat rise allowed) can safely handle. Could be 1V or 1000V. If

a piece of wire (of some length) has 1 ohm of resistance. 1 amp passed

through that wire will create 1 volt of drop across it and 1 watt of

heat. If the surface of the wire can dissipate that heat and stay below

the designed temperature it's safe. If the wire is operating in a

1,000,000 volt circuit with 1 amp flowing though it it's still going to

have 1 volt of drop across it creating the same 1 watt of heat.

| Quote: |

> b) I would recommend a 50A circuit breaker (push-pull or toggle) between the alternator and the battery side of the starter relay that can be

> operated by the pilot. It's bad when an alternator dies (open) and

> doesn't charge when in flight. It's much worse when an alternator dies

> (shorted) and starts draining the battery as fast as it can. In my

> airplane, their is a wire from the battery side of the starter solenoid

> to the master bus (where all the circuit breakers are) and the

> alternator is just another one on that bus. Of course there is also a 5A

> breaker for the "field" (really goes to the regulator and then to the

> rotor in the alternator).

>

Excellent point. But with that configuration, it doesn't make sense to put the starter contactor on the firewall because I'll still need to run the alternator wire all the way up to the front anyway. I was planning on an ANL50 for protection.

|

I'd put the starter contactor as close to where the other loads are as

possible. If you have the battery in the back for W&B considerations

you're going to have to run a heavy gauge cable to the starter in the

front. Put the contactor on the firewall then everything gets to take

advantage of this big heavy wire when you're not cranking.

I realize that you aren't required to build to Part 23 standards but

some of them do make sense. Part 23 requires that circuit protection

devices for loads critical to safety of flight be resettable or

replaceable by the flight crew while in flight. What stuff are you

powering with the alternator you'd like to have if you're flying VFR on

top at night over Nevada somewhere? How would you fly and replace an

NL50 fuse? Where would you put it so it would be handy? Carrying a spare

NL50? That's required too (in Part 23).

| Quote: |

> III) In all cases you first look at AC 43.13-1B

> (http://www.faa.gov/regulations_policies/advisory_circulars/index.cfm/go/document.information/documentid/99861)

> Table 11-9 to find the minimum size wire you need. This is the wire's

> maximum capacity regardless of length. It is based on the heat generated

> as the current flows though the wire's internal resistance (you know

> current * resistance per foot = watts of heat per foot). Select the wire

> the size dictated by the load and wire temperature rating. For a 50A

> circuit you need an 8 or 6 AWG wire depending on the temperature rating.

I'll look into that.

> Then, use AC 43.13-1B Figure 11-3 to determine the larger size wire

> needed if a longer wire run would have too much voltage drop for the

> circuit. Length is the round trip circuit so if you're using the

> airframe in a well bonded aluminum airplane the ground return is pretty

> much ignored. If you've got a nav light at the tip of a fiberglass wing,

> you have to calculate the length including the hot wire out to the load

> and the ground return wire length back.

Figure 11-3 in my copy is for intermittent load.

Yes, you're right. It's probably safer to design the alternator circuit

|

for continuous duty. If you design to Part 23 your loads should never

exceed 80% of generating capacity. This was really hard to do before

there were LED and HID landing lights. Old tube radios really wolfed

down the juice too.

This table (Figure 11-2) really sets the allowable voltage drop over the

length of the wire. In a circuit where wire size is dominated by current

carrying capacity like the relatively short alternator wire, this table

doesn't dictate wire size. If the alternator is mounted on the front of

the engine, it could be 8-12 wire feet to get to the circuit protection

device and another 4-6 wire feet to get back to the battery side of the

starter contactor. Worst case that's between 12' and 20' and of wire

(always use the next line up on the chart) and that says an 8 AWG wire.

Then is it an 8 AWG or a 6 AWG? Depends on the thermal rating of the wire.

Bill

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

billp(at)wwpc.com

Guest

|

Posted: Mon Jul 29, 2013 4:13 pm Post subject: Multi-hop wire sizing? Posted: Mon Jul 29, 2013 4:13 pm Post subject: Multi-hop wire sizing? |

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|