|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Steve Kelly

Joined: 08 Jul 2016

Posts: 18

|

Posted: Wed Mar 13, 2019 7:00 am Post subject: Starters Posted: Wed Mar 13, 2019 7:00 am Post subject: Starters |

|

|

Can someone with more knowledge than me on the subject, tell me the difference between a series wound motor and a PM motor. Also, does the series wound have more torque. Is it more durable.

I have a Skytech PM on my O-320 thats getting a little sluggish on the initial turn of the prop. While I'm aware that there may be other causes, confidence that my engine will start reliably is important.

I have heard good things about B&Cs starters. While they're more expensive, I guess you get what you pay for.

Steve

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Steve |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Mar 15, 2019 4:20 am Post subject: Starters Posted: Fri Mar 15, 2019 4:20 am Post subject: Starters |

|

|

At 10:00 AM 3/13/2019, you wrote:

| Quote: | --> AeroElectric-List message posted by: "Steve Kelly" <amsk22(at)gmail.com>

Can someone with more knowledge than me on the subject, tell me the difference

between a series wound motor and a PM motor. |

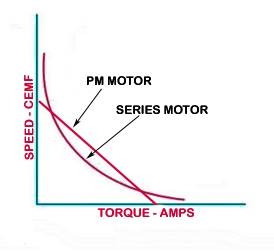

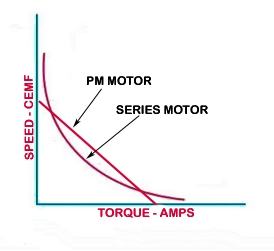

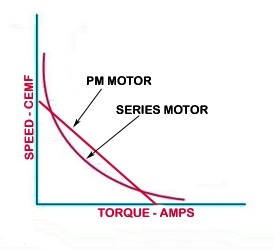

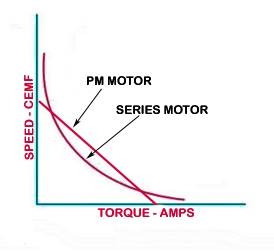

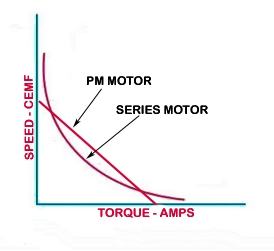

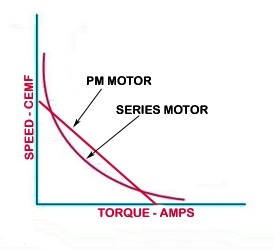

That's a question with a really big answer.

It fills a couple of volumes. It all depends

on the application. Series wound motors for

engine cranking are falling in popularity

for a host of interleaved trade-offs. Strong

influences on the shift to PM motors include

falling costs of rare earth magnets compared

to higher manufacturing costs for wound fields.

Wound field motors seem to find favor with

OEMs for diesel engines . . . a wound field

motor has a flatter speed torque curve

than PM motors under heavy load. They

generally outperform PM starters under

adverse conditions (cold, soggy battery,

high resistance in cranking loop).

[img]cid:.0[/img]

The downside of series wound motors include

poor load-speed regulation; an unloaded

PM motor has a limit on unloaded RPM.

A series wound motor's unloaded speed

is limited only by friction in the motor's

construction. Some designs are at risk

for self destruction if operated no-load.

There are a dozen trade-offs for deciding

which configuration to adopt for any given

application. Neither configuration is

'superior' to the other over the full

spectrum of operating characteristics.

| Quote: | | Also, does the series wound have more torque. |

Not 'more' but 'flatter' speed-torque

characteristics under heavy load . . .

| Quote: | | Is it more durable |

Not necessarily. Durability has more to

do with design details and manufacturing

quality than with choice of motors.

| Quote: |

I have a Skytech PM on my O-320 thats getting a

little sluggish on the initial turn of the prop.

While I'm aware that there may be other causes,

confidence that my engine will start reliably is important. |

Motor condition is but one of several reasons

for sluggish performance. The weakest link

in cranking chain is battery condition.

Just for grins, jumper your car battery

to the ship's battery and see how the engine

cranks. If there is marked improvement,

consider load/capacity checking your battery.

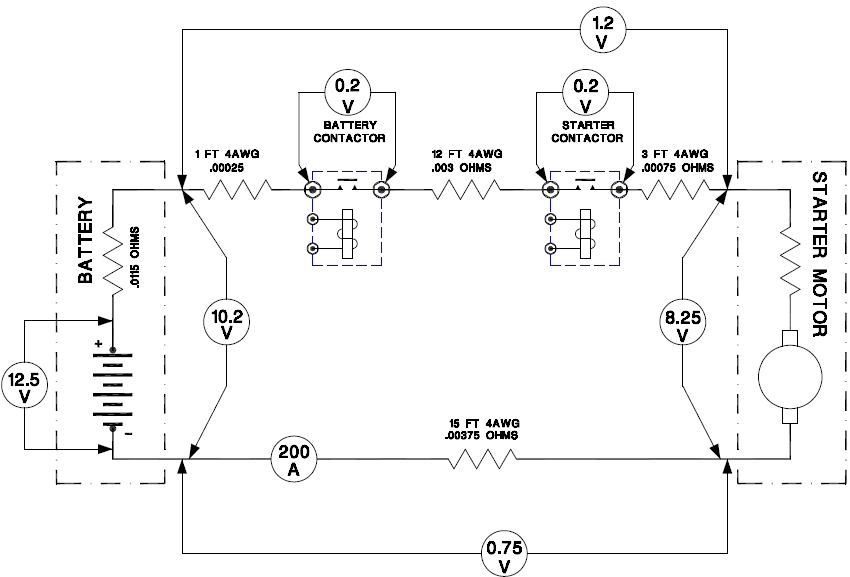

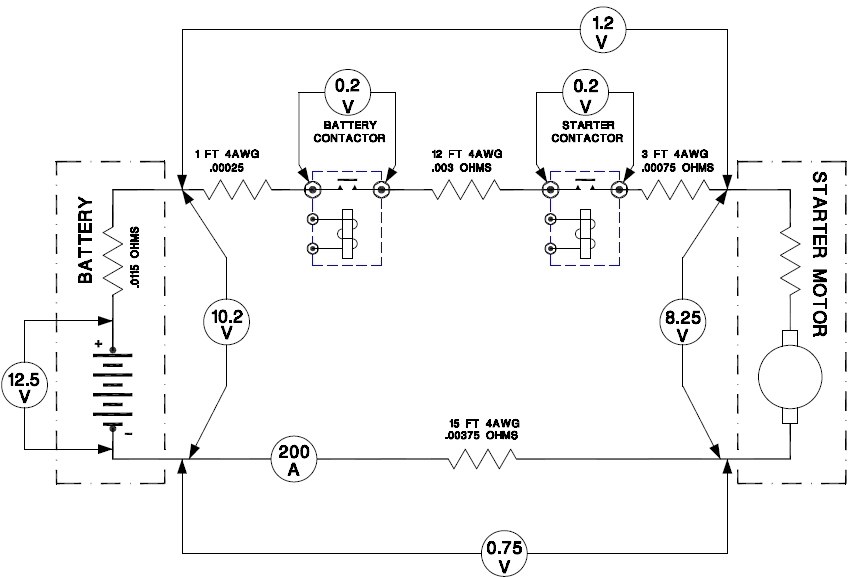

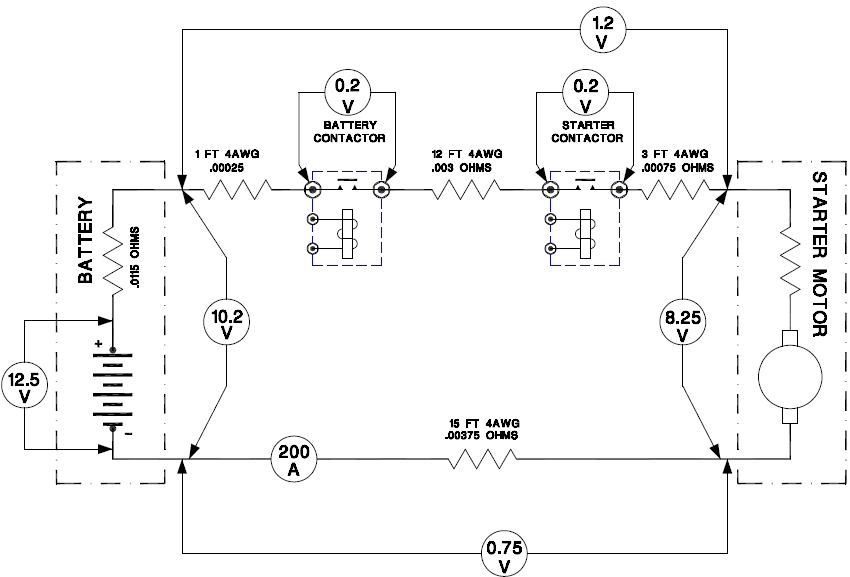

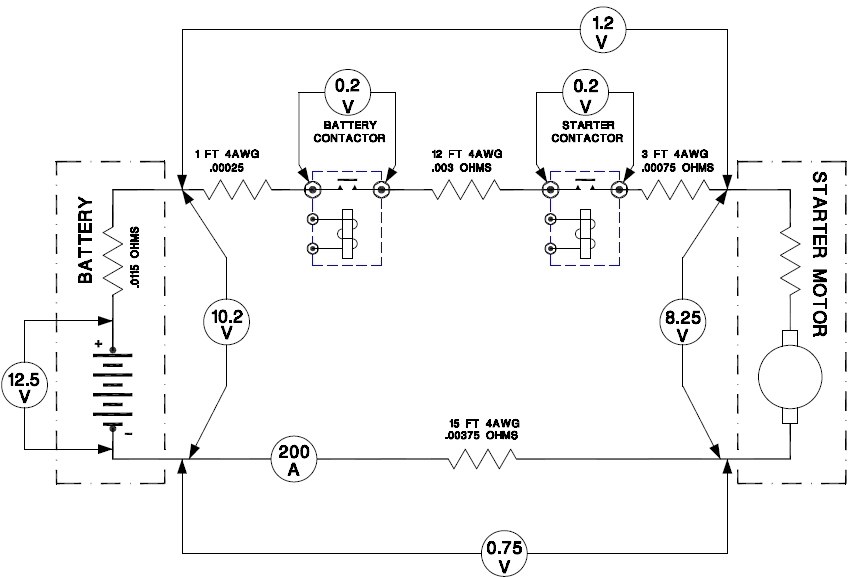

A least likely reason for diminished

performance is an increased voltage

drop in cranking power loop.

[img]cid:.1[/img]

It's expected that voltage available at the starter

motor is lower than battery voltage. Just how much

lower has an effect on cranking speed. I'd carefully

check out the cranking power loop, ESPECIALLY the

battery, before swapping out the starter.

| Quote: | | I have heard good things about B&Cs starters. While they're more expensive, I guess you get what you pay for. |

There were a number of discussions about the

differences for B&C versus other players

circa 1996. Here's one thread

https://tinyurl.com/y38w4ksz

In 23 years since, the various players

have had ample opportunity to secure their

position in the market based on perceived

value and demonstrated track record. Further,

I'm certain that many of the points cited

in the thread are not longer valid . . .

companies have changed hands and

sales volumes have promoted better

manufacturing techniques.

I have no recent knowledge of player

performance in today's starter market.

But I can share that Robinson Helicopter

was quite pleased with the performance

and weight advantages of the B&C

starters. They would swap B&C starters

onto brand new engines fitted with

factory supplied starters.

B&C would receive boxes of Robinson

starters pulled off engines taken

down for overhaul and returned for reman. No

matter how beat up and dirty the starters

were on the outside, the wearing parts

inside looked like they could go another

2,000 hours on the airplane.

I have no foundation to assert that

the major players do not offer good

value . . . but yes, in a free-market

competition for customers, you generally

do get what you pay for.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

25 KB |

| Viewed: |

10963 Time(s) |

|

| Description: |

|

| Filesize: |

129.21 KB |

| Viewed: |

10963 Time(s) |

|

|

|

| Back to top |

|

|

Steve Kelly

Joined: 08 Jul 2016

Posts: 18

|

Posted: Fri Mar 15, 2019 9:21 am Post subject: Starters Posted: Fri Mar 15, 2019 9:21 am Post subject: Starters |

|

|

Bob, Thank you for the reply. I will try to get out to the hanger early next week and check the voltage readings. The battery is a PC680 at three months old.  Do you have a method you would suggest to do a load/capacity check on it.Steve

On Fri, Mar 15, 2019 at 8:27 AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 10:00 AM 3/13/2019, you wrote:

| Quote: | --> AeroElectric-List message posted by: "Steve Kelly" <amsk22(at)gmail.com (amsk22(at)gmail.com)>

Can someone with more knowledge than me on the subject, tell me the difference

between a series wound motor and a PM motor. |

That's a question with a really big answer.

It fills a couple of volumes. It all depends

on the application. Series wound motors for

engine cranking are falling in popularity

for a host of interleaved trade-offs. Strong

influences on the shift to PM motors include

falling costs of rare earth magnets compared

to higher manufacturing costs for wound fields.

Wound field motors seem to find favor with

OEMs for diesel engines . . . a wound field

motor has a flatter speed torque curve

than PM motors under heavy load. They

generally outperform PM starters under

adverse conditions (cold, soggy battery,

high resistance in cranking loop).

[img]cid:16982567f58a8583ca21[/img]

The downside of series wound motors include

poor load-speed regulation; an unloaded

PM motor has a limit on unloaded RPM.

A series wound motor's unloaded speed

is limited only by friction in the motor's

construction. Some designs are at risk

for self destruction if operated no-load.

There are a dozen trade-offs for deciding

which configuration to adopt for any given

application. Neither configuration is

'superior' to the other over the full

spectrum of operating characteristics.

| Quote: | | Â Also, does the series wound have more torque. |

Not 'more' but 'flatter' speed-torque

characteristics under heavy load . . .

| Quote: | | Â Is it more durable |

Not necessarily. Durability has more to

do with design details and manufacturing

quality than with choice of motors.

| Quote: | Â

I have a Skytech PM on my O-320 thats getting a

little sluggish on the initial turn of the prop.

While I'm aware that there may be other causes,

confidence that my engine will start reliably is important. |

Motor condition is but one of several reasons

for sluggish performance. The weakest link

in cranking chain is battery condition.

Just for grins, jumper your car battery

to the ship's battery and see how the engine

cranks. If there is marked improvement,

consider load/capacity checking your battery.

A least likely reason for diminished

performance is an increased voltage

drop in cranking power loop.

[img]cid:16982567f58aa0d15412[/img]

It's expected that voltage available at the starter

motor is lower than battery voltage. Just how much

lower has an effect on cranking speed. I'd carefully

check out the cranking power loop, ESPECIALLY the

battery, before swapping out the starter.

| Quote: | |  I have heard good things about B&Cs starters. While they're more expensive, I guess you get what you pay for. |

There were a number of discussions about the

differences for B&C versus other players

circa 1996. Here's one thread

https://tinyurl.com/y38w4ksz

In 23 years since, the various players

have had ample opportunity to secure their

position in the market based on perceived

value and demonstrated track record. Further,

I'm certain that many of the points cited

in the thread are not longer valid . . .

companies have changed hands and

sales volumes have promoted better

manufacturing techniques.

I have no recent knowledge of player

performance in today's starter market.

But I can share that Robinson Helicopter

was quite pleased with the performance

and weight advantages of the B&C

starters. They would swap B&C starters

onto brand new engines fitted with

factory supplied starters.

B&C would receive boxes of Robinson

starters pulled off engines taken

down for overhaul and returned for reman. No

matter how beat up and dirty the starters

were on the outside, the wearing parts

inside looked like they could go another

2,000 hours on the airplane.

I have no foundation to assert that

the major players do not offer good

value . . . but yes, in a free-market

competition for customers, you generally

do get what you pay for.

Â

Â

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

25 KB |

| Viewed: |

10960 Time(s) |

|

| Description: |

|

| Filesize: |

129.21 KB |

| Viewed: |

10960 Time(s) |

|

_________________

Steve |

|

| Back to top |

|

|

argoldman(at)aol.com

Guest

|

Posted: Fri Mar 15, 2019 9:55 am Post subject: Starters Posted: Fri Mar 15, 2019 9:55 am Post subject: Starters |

|

|

While you are checking...check all of the cable connections for security and corrosionRich

Sent from my iPhone

On Mar 15, 2019, at 12:18 PM, Steve Kelly <amsk22(at)gmail.com (amsk22(at)gmail.com)> wrote:

| Quote: | Bob, Thank you for the reply. I will try to get out to the hanger early next week and check the voltage readings. The battery is a PC680 at three months old. Do you have a method you would suggest to do a load/capacity check on it.Steve

On Fri, Mar 15, 2019 at 8:27 AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 10:00 AM 3/13/2019, you wrote:

| Quote: | --> AeroElectric-List message posted by: "Steve Kelly" <amsk22(at)gmail.com (amsk22(at)gmail.com)>

Can someone with more knowledge than me on the subject, tell me the difference

between a series wound motor and a PM motor. |

That's a question with a really big answer.

It fills a couple of volumes. It all depends

on the application. Series wound motors for

engine cranking are falling in popularity

for a host of interleaved trade-offs. Strong

influences on the shift to PM motors include

falling costs of rare earth magnets compared

to higher manufacturing costs for wound fields.

Wound field motors seem to find favor with

OEMs for diesel engines . . . a wound field

motor has a flatter speed torque curve

than PM motors under heavy load. They

generally outperform PM starters under

adverse conditions (cold, soggy battery,

high resistance in cranking loop).

<b1f680f.jpg>

The downside of series wound motors include

poor load-speed regulation; an unloaded

PM motor has a limit on unloaded RPM.

A series wound motor's unloaded speed

is limited only by friction in the motor's

construction. Some designs are at risk

for self destruction if operated no-load.

There are a dozen trade-offs for deciding

which configuration to adopt for any given

application. Neither configuration is

'superior' to the other over the full

spectrum of operating characteristics.

| Quote: | | Also, does the series wound have more torque. |

Not 'more' but 'flatter' speed-torque

characteristics under heavy load . . .

| Quote: | | Is it more durable |

Not necessarily. Durability has more to

do with design details and manufacturing

quality than with choice of motors.

| Quote: |

I have a Skytech PM on my O-320 thats getting a

little sluggish on the initial turn of the prop.

While I'm aware that there may be other causes,

confidence that my engine will start reliably is important. |

Motor condition is but one of several reasons

for sluggish performance. The weakest link

in cranking chain is battery condition.

Just for grins, jumper your car battery

to the ship's battery and see how the engine

cranks. If there is marked improvement,

consider load/capacity checking your battery.

A least likely reason for diminished

performance is an increased voltage

drop in cranking power loop.

<b1f681f.jpg>

It's expected that voltage available at the starter

motor is lower than battery voltage. Just how much

lower has an effect on cranking speed. I'd carefully

check out the cranking power loop, ESPECIALLY the

battery, before swapping out the starter.

| Quote: | | I have heard good things about B&Cs starters. While they're more expensive, I guess you get what you pay for. |

There were a number of discussions about the

differences for B&C versus other players

circa 1996. Here's one thread

https://tinyurl.com/y38w4ksz

In 23 years since, the various players

have had ample opportunity to secure their

position in the market based on perceived

value and demonstrated track record. Further,

I'm certain that many of the points cited

in the thread are not longer valid . . .

companies have changed hands and

sales volumes have promoted better

manufacturing techniques.

I have no recent knowledge of player

performance in today's starter market.

But I can share that Robinson Helicopter

was quite pleased with the performance

and weight advantages of the B&C

starters. They would swap B&C starters

onto brand new engines fitted with

factory supplied starters.

B&C would receive boxes of Robinson

starters pulled off engines taken

down for overhaul and returned for reman. No

matter how beat up and dirty the starters

were on the outside, the wearing parts

inside looked like they could go another

2,000 hours on the airplane.

I have no foundation to assert that

the major players do not offer good

value . . . but yes, in a free-market

competition for customers, you generally

do get what you pay for.

Bob . . .

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Fri Mar 15, 2019 11:17 am Post subject: Starters Posted: Fri Mar 15, 2019 11:17 am Post subject: Starters |

|

|

That is a very common battery, any battery store will test it for you.

On Fri, Mar 15, 2019, 13:31 Steve Kelly <amsk22(at)gmail.com (amsk22(at)gmail.com)> wrote:

| Quote: | Bob, Thank you for the reply. I will try to get out to the hanger early next week and check the voltage readings. The battery is a PC680 at three months old.  Do you have a method you would suggest to do a load/capacity check on it.Steve

On Fri, Mar 15, 2019 at 8:27 AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 10:00 AM 3/13/2019, you wrote:

| Quote: | --> AeroElectric-List message posted by: "Steve Kelly" <amsk22(at)gmail.com (amsk22(at)gmail.com)>

Can someone with more knowledge than me on the subject, tell me the difference

between a series wound motor and a PM motor. |

That's a question with a really big answer.

It fills a couple of volumes. It all depends

on the application. Series wound motors for

engine cranking are falling in popularity

for a host of interleaved trade-offs. Strong

influences on the shift to PM motors include

falling costs of rare earth magnets compared

to higher manufacturing costs for wound fields.

Wound field motors seem to find favor with

OEMs for diesel engines . . . a wound field

motor has a flatter speed torque curve

than PM motors under heavy load. They

generally outperform PM starters under

adverse conditions (cold, soggy battery,

high resistance in cranking loop).

[img]cid:16982567f58a8583ca21[/img]

The downside of series wound motors include

poor load-speed regulation; an unloaded

PM motor has a limit on unloaded RPM.

A series wound motor's unloaded speed

is limited only by friction in the motor's

construction. Some designs are at risk

for self destruction if operated no-load.

There are a dozen trade-offs for deciding

which configuration to adopt for any given

application. Neither configuration is

'superior' to the other over the full

spectrum of operating characteristics.

| Quote: | | Â Also, does the series wound have more torque. |

Not 'more' but 'flatter' speed-torque

characteristics under heavy load . . .

| Quote: | | Â Is it more durable |

Not necessarily. Durability has more to

do with design details and manufacturing

quality than with choice of motors.

| Quote: | Â

I have a Skytech PM on my O-320 thats getting a

little sluggish on the initial turn of the prop.

While I'm aware that there may be other causes,

confidence that my engine will start reliably is important. |

Motor condition is but one of several reasons

for sluggish performance. The weakest link

in cranking chain is battery condition.

Just for grins, jumper your car battery

to the ship's battery and see how the engine

cranks. If there is marked improvement,

consider load/capacity checking your battery.

A least likely reason for diminished

performance is an increased voltage

drop in cranking power loop.

[img]cid:16982567f58aa0d15412[/img]

It's expected that voltage available at the starter

motor is lower than battery voltage. Just how much

lower has an effect on cranking speed. I'd carefully

check out the cranking power loop, ESPECIALLY the

battery, before swapping out the starter.

| Quote: | |  I have heard good things about B&Cs starters. While they're more expensive, I guess you get what you pay for. |

There were a number of discussions about the

differences for B&C versus other players

circa 1996. Here's one thread

https://tinyurl.com/y38w4ksz

In 23 years since, the various players

have had ample opportunity to secure their

position in the market based on perceived

value and demonstrated track record. Further,

I'm certain that many of the points cited

in the thread are not longer valid . . .

companies have changed hands and

sales volumes have promoted better

manufacturing techniques.

I have no recent knowledge of player

performance in today's starter market.

But I can share that Robinson Helicopter

was quite pleased with the performance

and weight advantages of the B&C

starters. They would swap B&C starters

onto brand new engines fitted with

factory supplied starters.

B&C would receive boxes of Robinson

starters pulled off engines taken

down for overhaul and returned for reman. No

matter how beat up and dirty the starters

were on the outside, the wearing parts

inside looked like they could go another

2,000 hours on the airplane.

I have no foundation to assert that

the major players do not offer good

value . . . but yes, in a free-market

competition for customers, you generally

do get what you pay for.

Â

Â

Bob . . .

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

25 KB |

| Viewed: |

10957 Time(s) |

|

| Description: |

|

| Filesize: |

129.21 KB |

| Viewed: |

10957 Time(s) |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1706

Location: Sun Lakes AZ

|

Posted: Fri Mar 15, 2019 12:38 pm Post subject: Starters Posted: Fri Mar 15, 2019 12:38 pm Post subject: Starters |

|

|

Odyssey batteries are often prematurely aged by keeping on a battery

maintainer. If you contact Odyssey they can give you a rejuvenation

protocol to restore the battery to near full capacity. I'm at about 4

years on my Odyssey 925 in the Aridzona heat, and still working fine.

On 3/15/2019 12:15 PM, Sebastien wrote:

| Quote: | That is a very common battery, any battery store will test it for you.

On Fri, Mar 15, 2019, 13:31 Steve Kelly <amsk22(at)gmail.com

<mailto:amsk22(at)gmail.com>> wrote:

Bob, Thank you for the reply. I will try to get out to the hanger

early next week and check the voltage readings. The battery is a

PC680 at three months old.  Do you have a method you would suggest

to do a load/capacity check on it.

Steve

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Mar 16, 2019 6:06 am Post subject: Starters Posted: Sat Mar 16, 2019 6:06 am Post subject: Starters |

|

|

At 02:15 PM 3/15/2019, you wrote:

| Quote: | That is a very common battery, any battery store will test it for you.

On Fri, Mar 15, 2019, 13:31 Steve Kelly <amsk22(at)gmail.com (amsk22(at)gmail.com)> wrote:

Bob, Thank you for the reply. I will try to get out to the hanger early next week and check the voltage readings. The battery is a PC680 at three months old.  Do you have a method you would suggest to do a load/capacity check on it. |

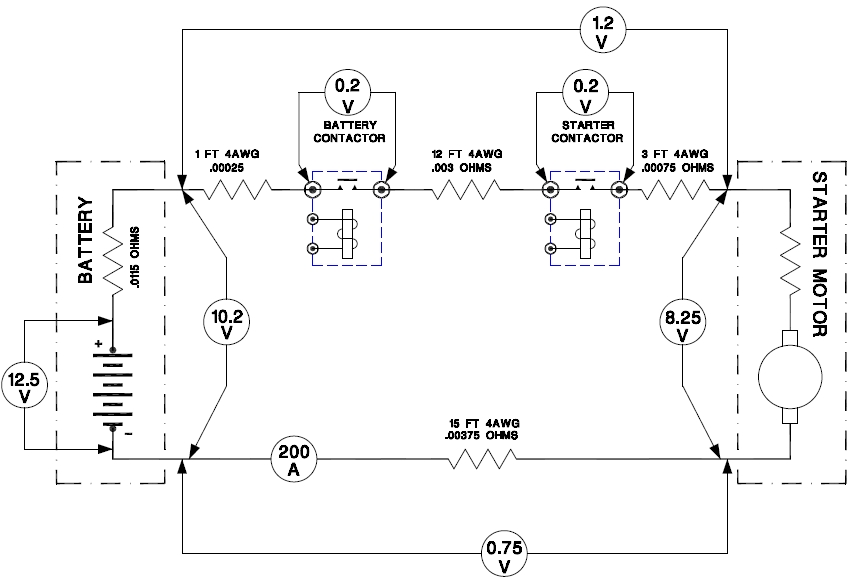

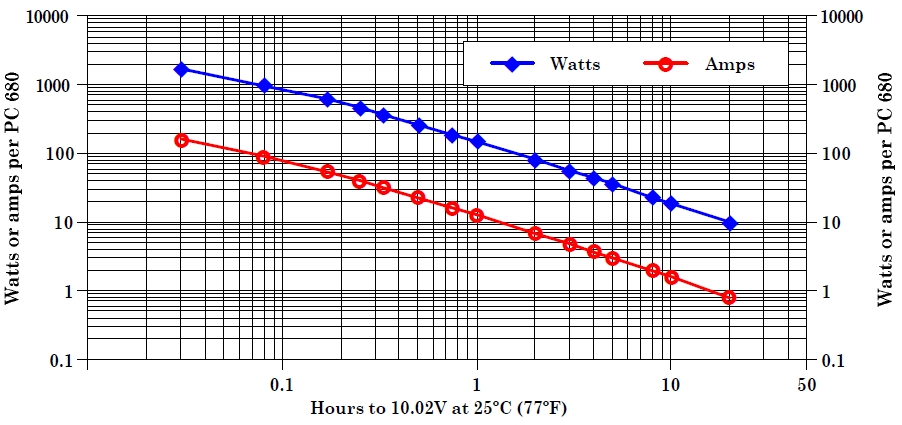

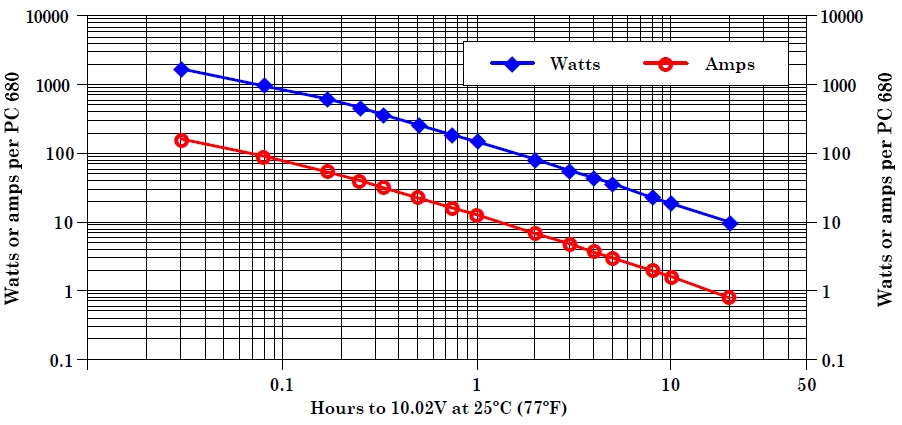

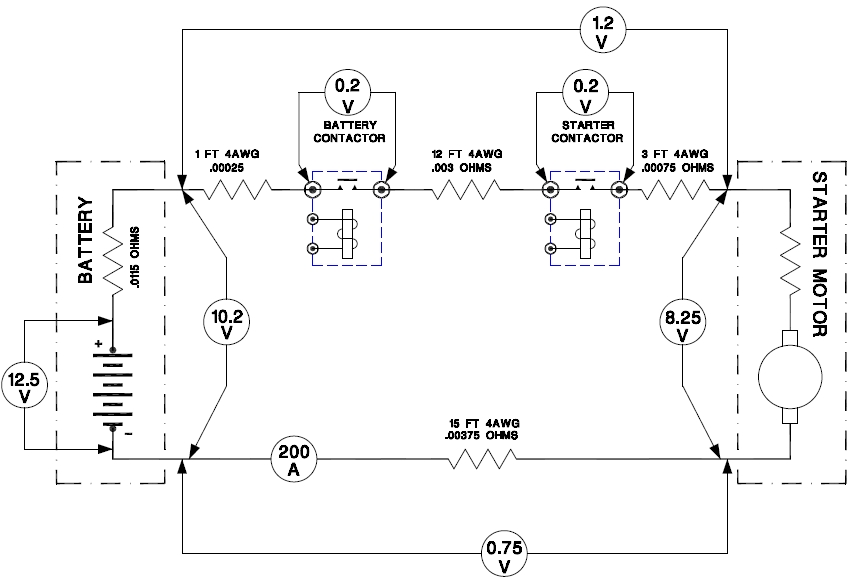

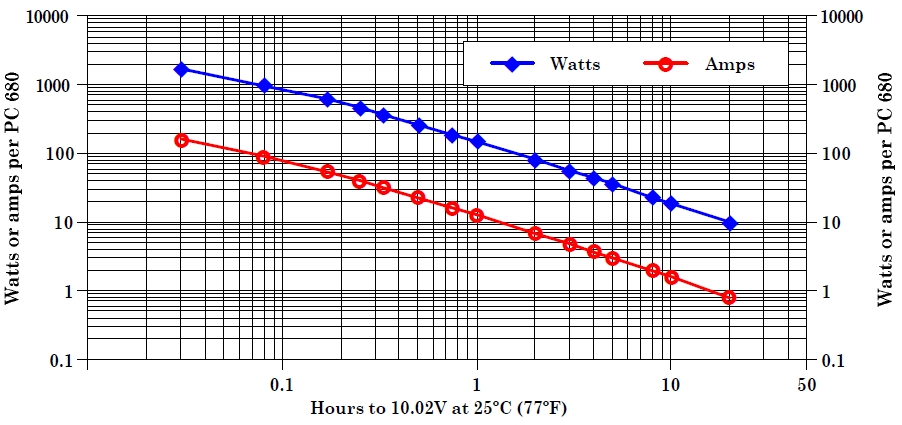

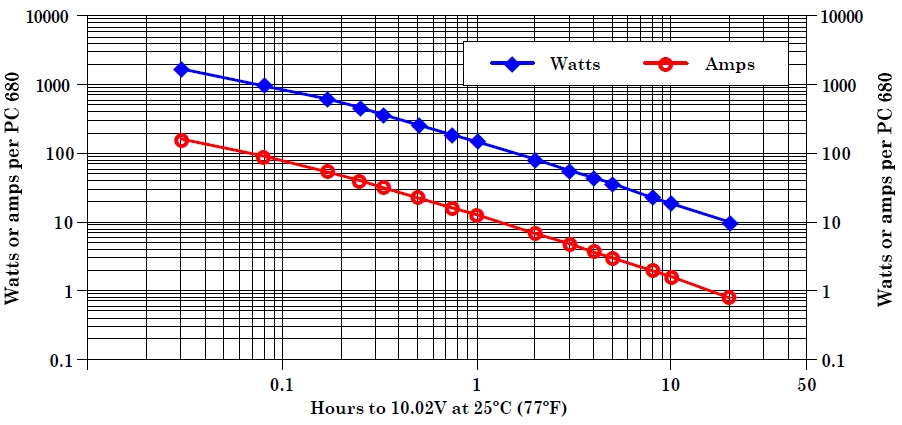

That's a pretty fresh battery . . . this suggests

the problem is elsewhere. However, in answer to

your testing questions, I'll suggest that

every owner of an aircraft should also own

something like this

https://tinyurl.com/yag4529y

This LOAD tester allows you to load the battery

to an output of 9 volts while waiting for the

15 second timer light to go out. Note the current

at the end of 15 seconds . . . it should be in

excess of 200A for small engines, 300A for larger

engines. This test confirms the battery's avbility

to grunt the extra-ordinary demands for cranking

the engine.

A CAPACITY test seeks to quantify the battery's

ENERGY content . . . which is entirely separate

from the capability to grunt a cranking load.

There are some rather small batteries that have

demonstrated the ability to crank a turbine

engine

https://tinyurl.com/yye6znqp

But this product wouldn't run the aircraft's

critical systems for very long after the

alternator quits. There are dozens of 'tiny'

products that offer a similar utility

https://tinyurl.com/y2hzkq9l

The way to cap check your battery is to set

up your panel to operate your Plan-B (alternator

out) electrical loads and monitor battery voltage

with a voltmeter. The time it takes to reduce

battery voltage to 10V (the lower limit for

your avionics to operate).

For example, a NEW PC680 has the following

ENERGY delivery capability.

[img]cid:.0[/img]

Assume a 4A endurance load. The curves say you're

good to 3 hours. Here you have to tailor the question

to match your own endurance requirements. If one hour

meets your own Plan-B design goals, then according

to the chart, the new battery is good for about 10A.

Actually, you would want to rate the battery for about

8A given that maintenance protocols suggest replacing

the battery at 75% of new capacity.

Then there's the real-life test . . . turn on the

goodies, start the clock, watch the voltage, measure

the time then recharge the battery. If that time

is equal to or greater than your design goals, then

you're good to fly.

How old is your starter? It MIGHT be that brushes

and/or commutator are worn to the point of producing

degraded performance.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

224.52 KB |

| Viewed: |

10948 Time(s) |

|

|

|

| Back to top |

|

|

Steve Kelly

Joined: 08 Jul 2016

Posts: 18

|

Posted: Mon Mar 18, 2019 7:37 am Post subject: Starters Posted: Mon Mar 18, 2019 7:37 am Post subject: Starters |

|

|

Bob. Thanks for the help. I had a chance to do the voltage tests like you suggested. They were fairly similar to your your're example. While cranking the voltage at the battery was around 10.5 and at the starter it was between 7.5 and 8.5 volts. I also acquired a load tester. At the end of the 15 sec test current was about 330 amps. Battery voltage dropped to 11.3 volts. The starter is a Sky Tec 149xlt. It's about 3 years old and has 170 hours on it. This is probably the smallest starter Sky Tec makes. Not sure if it's the weakest one. Other contributing factors are cooler weather, fresh engine overhaul, and a lightweight prop. Still, the starter should spin it better than it is. Do worn starters draw the battery down faster?

Also, just to be clear, replacing the battery at 75% refers to the time it takes to drop to 10 volts, correct? In you're example above when the PC680 gets to 10v in 2.25 hours it's time to consider replacement.

Steve

Â

Â

On Sat, Mar 16, 2019 at 10:13 AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 02:15 PM 3/15/2019, you wrote:

| Quote: | That is a very common battery, any battery store will test it for you.

On Fri, Mar 15, 2019, 13:31 Steve Kelly <amsk22(at)gmail.com (amsk22(at)gmail.com)> wrote:

|

Bob,ÃÂ Thank you for the reply.ÃÂ I will try to get out to the hanger early next week and check the voltage readings.ÃÂ The battery is a PC680 at three months old.ÃÂ Ã Do you have a method you would suggest to do a load/capacity check on it.

That's a pretty fresh battery . . . this suggests

the problem is elsewhere. However, in answer to

your testing questions, I'll suggest that

every owner of an aircraft should also own

something like this

https://tinyurl.com/yag4529y

This LOAD tester allows you to load the battery

to an output of 9 volts while waiting for the

15 second timer light to go out. Note the current

at the end of 15 seconds . . . it should be in

excess of 200A for small engines, 300A for larger

engines. This test confirms the battery's avbility

to grunt the extra-ordinary demands for cranking

the engine.

A CAPACITY test seeks to quantify the battery's

ENERGY content . . . which is entirely separate

from the capability to grunt a cranking load.

There are some rather small batteries that have

demonstrated the ability to crank a turbine

engine

https://tinyurl.com/yye6znqp

But this product wouldn't run the aircraft's

critical systems for very long after the

alternator quits. There are dozens of 'tiny'

products that offer a similar utility

https://tinyurl.com/y2hzkq9l

The way to cap check your battery is to set

up your panel to operate your Plan-B (alternator

out) electrical loads and monitor battery voltage

with a voltmeter. The time it takes to reduce

battery voltage to 10V (the lower limit for

your avionics to operate).

For example, a NEW PC680 has the following

ENERGY delivery capability.

[img]cid:169915204ebb1ccea621[/img]

Assume a 4A endurance load. The curves say you're

good to 3 hours. Here you have to tailor the question

to match your own endurance requirements. If one hour

meets your own Plan-B design goals, then according

to the chart, the new battery is good for about 10A.

Actually, you would want to rate the battery for about

8A given that maintenance protocols suggest replacing

the battery at 75% of new capacity.

Then there's the real-life test . . . turn on the

goodies, start the clock, watch the voltage, measure

the time then recharge the battery. If that time

is equal to or greater than your design goals, then

you're good to fly.

How old is your starter? It MIGHT be that brushes

and/or commutator are worn to the point of producing

degraded performance.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

224.52 KB |

| Viewed: |

10922 Time(s) |

|

_________________

Steve |

|

| Back to top |

|

|

millner(at)me.com

Guest

|

Posted: Mon Mar 18, 2019 9:19 am Post subject: Starters Posted: Mon Mar 18, 2019 9:19 am Post subject: Starters |

|

|

2-3 volts is a huge voltage drop. You need to determine where thatâs happening... SkyTec has a troubleshooting chart to help you find the bad actor

Sent from my iPhone

On Mar 18, 2019, at 8:35 AM, Steve Kelly <amsk22(at)gmail.com (amsk22(at)gmail.com)> wrote:

| Quote: | Bob. Thanks for the help. I had a chance to do the voltage tests like you suggested. They were fairly similar to your your're example. While cranking the voltage at the battery was around 10.5 and at the starter it was between 7.5 and 8.5 volts. I also acquired a load tester. At the end of the 15 sec test current was about 330 amps. Battery voltage dropped to 11.3 volts. The starter is a Sky Tec 149xlt. It's about 3 years old and has 170 hours on it. This is probably the smallest starter Sky Tec makes. Not sure if it's the weakest one. Other contributing factors are cooler weather, fresh engine overhaul, and a lightweight prop. Still, the starter should spin it better than it is. Do worn starters draw the battery down faster?

Also, just to be clear, replacing the battery at 75% refers to the time it takes to drop to 10 volts, correct? In you're example above when the PC680 gets to 10v in 2.25 hours it's time to consider replacement.

Steve

On Sat, Mar 16, 2019 at 10:13 AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 02:15 PM 3/15/2019, you wrote:

| Quote: | That is a very common battery, any battery store will test it for you.

On Fri, Mar 15, 2019, 13:31 Steve Kelly <amsk22(at)gmail.com (amsk22(at)gmail.com)> wrote:

|

Bob,Ã Thank you for the reply.Ã I will try to get out to the hanger early next week and check the voltage readings.Ã The battery is a PC680 at three months old.Ã Ã Do you have a method you would suggest to do a load/capacity check on it.

That's a pretty fresh battery . . . this suggests

the problem is elsewhere. However, in answer to

your testing questions, I'll suggest that

every owner of an aircraft should also own

something like this

https://tinyurl.com/yag4529y

This LOAD tester allows you to load the battery

to an output of 9 volts while waiting for the

15 second timer light to go out. Note the current

at the end of 15 seconds . . . it should be in

excess of 200A for small engines, 300A for larger

engines. This test confirms the battery's avbility

to grunt the extra-ordinary demands for cranking

the engine.

A CAPACITY test seeks to quantify the battery's

ENERGY content . . . which is entirely separate

from the capability to grunt a cranking load.

There are some rather small batteries that have

demonstrated the ability to crank a turbine

engine

https://tinyurl.com/yye6znqp

But this product wouldn't run the aircraft's

critical systems for very long after the

alternator quits. There are dozens of 'tiny'

products that offer a similar utility

https://tinyurl.com/y2hzkq9l

The way to cap check your battery is to set

up your panel to operate your Plan-B (alternator

out) electrical loads and monitor battery voltage

with a voltmeter. The time it takes to reduce

battery voltage to 10V (the lower limit for

your avionics to operate).

For example, a NEW PC680 has the following

ENERGY delivery capability.

<10a704b8.jpg>

Assume a 4A endurance load. The curves say you're

good to 3 hours. Here you have to tailor the question

to match your own endurance requirements. If one hour

meets your own Plan-B design goals, then according

to the chart, the new battery is good for about 10A.

Actually, you would want to rate the battery for about

8A given that maintenance protocols suggest replacing

the battery at 75% of new capacity.

Then there's the real-life test . . . turn on the

goodies, start the clock, watch the voltage, measure

the time then recharge the battery. If that time

is equal to or greater than your design goals, then

you're good to fly.

How old is your starter? It MIGHT be that brushes

and/or commutator are worn to the point of producing

degraded performance.

Bob . . .

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Mar 18, 2019 9:31 am Post subject: Starters Posted: Mon Mar 18, 2019 9:31 am Post subject: Starters |

|

|

At 12:09 PM 3/18/2019, you wrote:

| Quote: | 2-3 volts is a huge voltage drop. You need to determine where thatâs happening... SkyTec has a troubleshooting chart to help you find the bad actor

|

Agreed. Use a voltmeter between

(1) battery(+) and starter power terminal

while cranking.

(2) battery(-) and crankcase.

Where is your battery located with respect

to starter i.e. how long are the wires

and what gage are they?

This is a NEW condition . . . used to crank

right smartly and only now sluggish?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Steve Kelly

Joined: 08 Jul 2016

Posts: 18

|

Posted: Mon Mar 18, 2019 1:51 pm Post subject: Starters Posted: Mon Mar 18, 2019 1:51 pm Post subject: Starters |

|

|

Bob, The slow prop became more noticeable after rebuilding the engine last summer. Fresh cylinders along with upping the compression ratio from 7 to 8.5. Â

The battery and solenoids are located on the firewall. So the cables are not very long. Maybe 5' total and 2' for ground. They are B&Cs 4 ga. weld cable.

Looking at the measurements I made yesterday, the drop on the negative was small, maybe .3 volts. The biggest drop was somewhere between the battery and in side of the starter solenoid.  10.5 volts down to around 8. Didn't check either side of the battery contactor as the battery was getting low. I have a brass strap that connects between the two contactors. 1/2' wide by about 4" long. Do you think this may not be adequate. Either that or the battery contactor. I will check the voltages there when I get back out to the hanger. Â

Thanks, Steve

On Mon, Mar 18, 2019 at 1:37 PM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 12:09 PM 3/18/2019, you wrote:

| Quote: | 2-3 volts is a huge voltage drop. You need to determine where thatââ¬â¢s happening... SkyTec has a troubleshooting chart to help you find the bad actor

|

Agreed. Use a voltmeter between

(1) battery(+) and starter power terminal

while cranking.

(2) battery(-) and crankcase.

Where is your battery located with respect

to starter i.e. how long are the wires

and what gage are they?

This is a NEW condition . . . used to crank

right smartly and only now sluggish?

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Steve |

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1706

Location: Sun Lakes AZ

|

Posted: Mon Mar 18, 2019 6:03 pm Post subject: Starters Posted: Mon Mar 18, 2019 6:03 pm Post subject: Starters |

|

|

Your compression change is not significant in terms of starter cranking.

A PC680 easily cranks an 0-360 with 8.5 compression.

Check to see that each connection is at proper torque at the max end of

scale for bolt size. Check the drop across the solenoid.

Now that you have run the battery down a fair amount, charge it at

around 3 amps until full charge. Should have a resting voltage of 12.9

to 13.0 four or more hours after off charger. If less, may need

rejuvenation through several discharge, charge cycles.

On 3/18/2019 2:49 PM, Steve Kelly wrote:

| Quote: | Bob,

The slow prop became more noticeable after rebuilding the engine last

summer. Fresh cylinders along with upping the compression ratio from 7

to 8.5.

The battery and solenoids are located on the firewall. So the cables

are not very long. Maybe 5' total and 2' for ground. They are B&Cs 4

ga. weld cable.

Looking at the measurements I made yesterday, the drop on the

negative was small, maybe .3 volts. The biggest drop was somewhere

between the battery and in side of the starter solenoid.  10.5 volts

down to around 8. Didn't check either side of the battery contactor as

the battery was getting low. I have a brass strap that connects between

the two contactors. 1/2' wide by about 4" long. Do you think this may

not be adequate. Either that or the battery contactor. I will check

the voltages there when I get back out to the hanger.

Thanks, Steve

On Mon, Mar 18, 2019 at 1:37 PM Robert L. Nuckolls, III

<nuckolls.bob(at)aeroelectric.com <mailto:nuckolls.bob(at)aeroelectric.com>>

wrote:

At 12:09 PM 3/18/2019, you wrote:

> 2-3 volts is a huge voltage drop. You need to determine where

> thatââ¬â¢s happening... SkyTec has a troubleshooting chart to help

> you find the bad actor

>

Agreed. Use a voltmeter between

(1) battery(+) and starter power terminal

while cranking.

(2) battery(-) and crankcase.

Where is your battery located with respect

to starter i.e. how long are the wires

and what gage are they?

This is a NEW condition . . . used to crank

right smartly and only now sluggish?

__

__ Â Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|