|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

kenryan

Joined: 20 Oct 2009

Posts: 429

|

Posted: Mon Mar 18, 2019 7:41 am Post subject: Battery BMS failures? Posted: Mon Mar 18, 2019 7:41 am Post subject: Battery BMS failures? |

|

|

On the Aircraft Spruce page for the Aerovoltz battery, under the "Overview" tab, the following text appears:

"An Aerovoltz external BMS is in a prototype stage and will be made available to all Lithium Battery owners in the near future. Putting the unit internally dramatically drives up the battery cost and all batteries will wear out eventually so making it external will keep the cost of ownership lower down the road when it comes time to replace.

The current BMS systems on the market are very sensitive to damage and it can disable a perfectly good battery that will then need replacing. We donât feel thatâs fair to our customers."

Has anyone heard about a rash of BMS failures?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Mar 18, 2019 9:48 am Post subject: Battery BMS failures? Posted: Mon Mar 18, 2019 9:48 am Post subject: Battery BMS failures? |

|

|

| Quote: |

Has anyone heard about a rash of BMS failures?

|

Good catch Ken. I'd be interested

(as would we all) in knowing what

kind of BMS failures have occurred.

Unfortunately, every battery failure

I've tried to follow up with the

manufacture was greeted with a stone

wall . . . take that back . . . used

to get great data dumps from Skip

Koss on Concorde product issues.

I've asked to be the recipient of any

failed batteries (or other devices)

so that I might disassemble for close

examination in a quest for answers . . .

but those opportunities are rare

to non-existent.

The outcome of non-communication is

ignorant assumption which gets traded

around the various venues . . . with

demonstrable data creep.

The first difficulty we have is defining

"Battery Management System". Many

lithium cylindrical cells are fitted

with dead short mitigation and are

advertised to be fitted with a "BMS".

Batteries and array of series-parallel

cells might include a cell balancing

module and advertised to include

a built-in "BMS".

Then there are full-up BMS like EarthX

and True Blue that will manage overheat,

over volts, charge balance/limiting,

fault mitigation and, in True Blue

case, comfortable management of vented

gasses in case the unthinkable does

happen.

Unless we're favored with a published

product performance specification for

the failure being studied, any assertions

about 'BMS failure' are exceedingly short

on useful data.

Keep your ears to the ground guys . . .

we might get lucky . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

echristley(at)att.net

Guest

|

Posted: Mon Mar 18, 2019 4:47 pm Post subject: Battery BMS failures? Posted: Mon Mar 18, 2019 4:47 pm Post subject: Battery BMS failures? |

|

|

I have heard about the desulfater (sp?) charges killing the electronics due to their large voltage spikes. The battery manufacturers themselves warn about those.

Otherwise....nada.

On Monday, March 18, 2019, 11:42:05 AM EDT, Ken Ryan <keninalaska(at)gmail.com> wrote:

On the Aircraft Spruce page for the Aerovoltz battery, under the "Overview" tab, the following text appears:

"An Aerovoltz external BMS is in a prototype stage and will be made available to all Lithium Battery owners in the near future. Putting the unit internally dramatically drives up the battery cost and all batteries will wear out eventually so making it external will keep the cost of ownership lower down the road when it comes time to replace.

The current BMS systems on the market are very sensitive to damage and it can disable a perfectly good battery that will then need replacing. We donât feel thatâs fair to our customers."

Has anyone heard about a rash of BMS failures?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Tue Mar 19, 2019 12:34 pm Post subject: Battery BMS failures? Posted: Tue Mar 19, 2019 12:34 pm Post subject: Battery BMS failures? |

|

|

On 3/18/2019 12:47 PM, Robert L. Nuckolls, III wrote:

| Quote: | [snip]

Then there are full-up BMS like EarthX

and True Blue that will manage overheat,

over volts, charge balance/limiting,

fault mitigation and, in True Blue

case, comfortable management of vented

gasses in case the unthinkable does

happen.

Unless we're favored with a published

product performance specification for

the failure being studied, any assertions

about 'BMS failure' are exceedingly short

on useful data.

Keep your ears to the ground guys . . .

we might get lucky . . .

Bob . . . |

Bob,

Speaking of BMS, perhaps you can explain (since EarthX seems unable) why EarthX batteries, with their 'full BMS', have a limit on alternator current capability based on their battery capacity. I am unable to see why a BMS that can manage individual cell charging, and protect individual cells plus the entire battery, is unable to limit overall charge current to the battery to a safe level. I've repeatedly asked that question of their spokesperson on the VAF (RV) forum, and gotten words without answers.

Charlie

Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2] [/url] Virus-free. www.avast.com [url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2] [/url]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Mar 20, 2019 7:15 am Post subject: Battery BMS failures? Posted: Wed Mar 20, 2019 7:15 am Post subject: Battery BMS failures? |

|

|

| Quote: | Bob,

Speaking of BMS, perhaps you can explain (since EarthX seems unable) why EarthX batteries, with their 'full BMS', have a limit on alternator current capability based on their battery capacity. I am unable to see why a BMS that can manage individual cell charging, and protect individual cells plus the entire battery, is unable to limit overall charge current to the battery to a safe level. I've repeatedly asked that question of their spokesperson on the VAF (RV) forum, and gotten words without answers.

Charlie |

Interesting question . . .

I've oft asserted that batteries are

like houseplants. Given the right treatment

in proper proportions and protected from

deleterious stress, they will 'bloom'

and thrive.

But the term 'battery' is not quantified

and the selection of a battery is to

craft a kind of marriage between a host

of players not the least of which are

the engine driven power source(s) and

design goals for normal and abnormal

operations.

Lithium cells are the orchids of the

battery family . . . capable of extra-

ordinary performance in some respects

but exceedingly sensitive to

stress largely tolerated or

shrugged off by the likes of

Flooded, SVLA, gell and NiCad

technologies.

Lithium is extra-ordinarily vulnerable

to over and under voltage conditions.

Hence the 'real' BMS will strive to

operate the array of cells between

about 20 and 90 percent of charge.

This is a goal stated by the electric

and hybrid car folks. No doubt, EarthX

has their own numbers but what ever

the numbers, ignoring them risks

premature battery failure.

Then there's temperature . . . stuffing

energy back into a lithium array

MUST raise the chemistry's temperature

as does prolonged heavy rate discharge.

So the agile BMS watches temperatures

and strives to limit those effects

on the cells irrespective of system

demands from the outside.

External hard faults cause spectacular

current flows with a new constellation

of risks for catastrophic failures.

A BMS tailored for engine cranking

expects to see some really high

current flows for short periods of

time . . . but it must differentiate

between starter inrush/engine spin-up

and a hard fault.

I've mentioned that the enclosure

for a True Blue, TC/TSO battery

is filled with electronics . . .

electronics with agility and robustness

to accomplish all these things to

prevent premature failure while packaged

to keep the rare catastrophic failure

from migrating to the rest of the

aircraft.

True Blue batteries are used on twin

turbine aircraft with starter generators

up to and including 400A per side or

800A of recharge capability. Starter

inrush is typically 1500-2000 amps

followed by spin-up currents on the

order of 500-700A lasting 20-30

seconds. My hat is off to the folks

who crafted an array of silicon that

can operate in series with those loads

yet meet design goals for safety and

battery life.

AeroVoltz seems to be moving toward

offering an EXTERNAL BMS for their

product line . . . methinks a fine

idea. That way you don't trash a

bunch of perfectly good transistors

along with a shot battery.

The most difficult thing for a BMS

to do is throttle currents . . . in

either a charge or discharge mode.

The series connected control devices

are either switched on hard (saturated)

or totally open (off). This offers

the smallest form factor of electronics

to manage such current levels.

Battery recharge limits are largely

a thermal management issue. The

very low internal impedance of the

lithium cell COMBINED with its

low mass raises concerns for overheating

during prolonged high rates of charge.

True Blue isn't immune to these

forces either but they're designed to

work in a world of currents a magnitude

greater than piston driven light aircraft.

EarthX and contemporaries are not immune

from the need to make compromises in design

goals. They are marketing good cranking

performance and light weight. Light

weight generally brings extra-ordinary

requirements in thermal management.

Light weight and small size puts limits

on capacity . . . largely independent

of short term cranking ability.

Given the fact that a BMS cannot 'throttle'

current into or out of the battery,

they must be cognizant of the risks for

marrying their 'orchid' to a system

recently divorced from a 'bromeliad'

that may not easily bloom but it doesn't

lay down and die when insulted.

So what's the responsible supplier of

light cranking batteries to do when

marketing to relative technical

novices about the care and feeding

of their products. To be sure, lots

of their batteries are being married

to systems that already have alternators

that are too big.

If the engine starts easily when

smartly cranked time needed to recharge

is limited even if too fast. If the

operator NEVER allows the battery to

be deeply discharged followed by

an in-situ recharge by the ship's

too-big alternator . . . then risks

to the battery are low.

At the same time, the operator purchased

"light" and "whippy-starting" and made

no demands for electrical and thermal

robustness. So it makes sense that

EarthX would recommend limiting the

size of the alternator depending

on size of battery . . . not a very

realistic expectation but a good

CYA move nonetheless.

This raises a recollection of experiences

with another shotgun wedding between

poorly matched components. Waayyy

back when we got all exercised about

what was then a big quantum leap

in light weight, robust cranking

batteries with flooded NiCads.

After setting a few airplanes on fire

with a marriage of nicad and twin

turbines, powers-that=be decided

that the BEST thing to do was add

a remote reading battery temperature

meter paired with yellow warning

and red danger lights designed

to assist crews in managing their

'orchids' to prevent overheat

and thermal runaway.

I argued then that we could craft

an accessory to the starter-generator

controllers that would automatically

adjust bus voltage in response to

battery overheat. That wasn't well

received so we added another thing

on the panel that was harder to

install and drove up pilot work

loads.

The same thing could be done here.

The BMS for the alternator/lithium

marriage could easily include an

regulator that would prevent an

alternator of ANY SIZE from abusing

the battery . . . maybe AeroVoltz

will do it.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 261

|

Posted: Wed Mar 20, 2019 10:37 am Post subject: Re: Battery BMS failures? Posted: Wed Mar 20, 2019 10:37 am Post subject: Re: Battery BMS failures? |

|

|

| Charlie England wrote: | | Speaking of BMS, perhaps you can explain (since EarthX seems unable) why EarthX batteries, with their 'full BMS', have a limit on alternator current capability based on their battery capacity. I am unable to see why a BMS that can manage individual cell charging, and protect individual cells plus the entire battery, is unable to limit overall charge current to the battery to a safe level. I've repeatedly asked that question of their spokesperson on the VAF (RV) forum, and gotten words without answers. |

My guess is that it's a limitation of the cell balancing circuitry in the BMS. As a cell within the battery reaches full charge, the BMS puts a resistance across it (either a fixed resistor hard-switched across the cell or a linear-mode transistor) to burn the current that would otherwise overcharge the cell while the others continue to charge. There must be a limit to the power that this system can dissipate, which may explain the alternator output limitation.

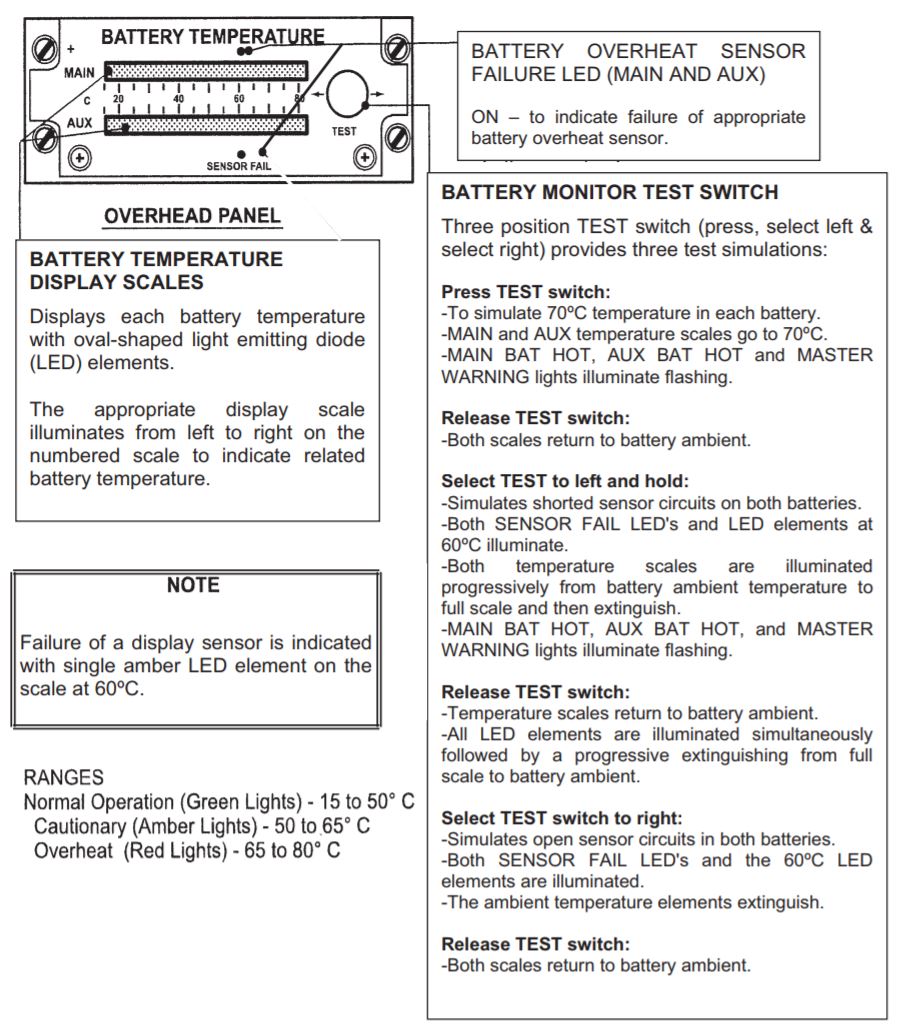

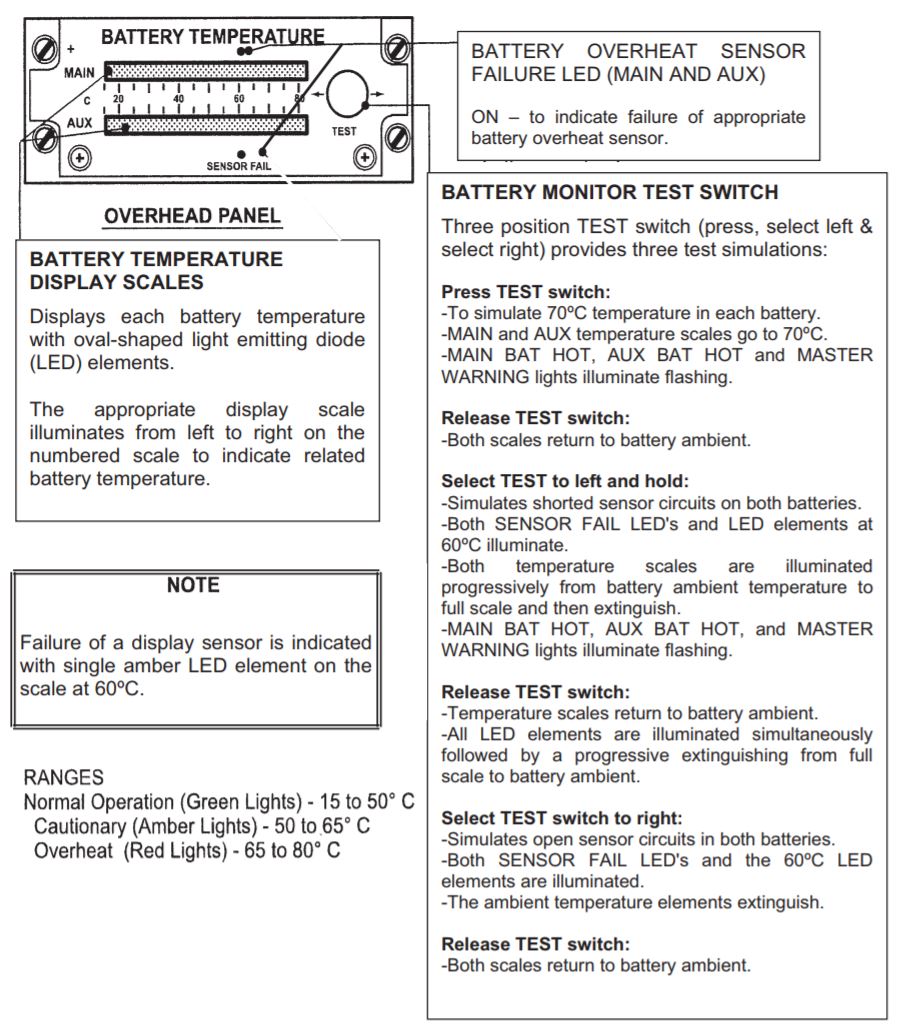

| Robert L. Nuckolls, III wrote: | | After setting a few airplanes on fire with a marriage of nicad and twin turbines, powers-that=be decided that the BEST thing to do was add a remote reading battery temperature meter paired with yellow warning and red danger lights designed to assist crews in managing their 'orchids' to prevent overheat and thermal runaway. |

Indeed, the deHavilland DHC-8-202 that I flew in a previous life was fitted with battery temperature gauges on the overhead panel (just below the left fire t-handle in the linked image).

https://bitly.com/2uj9V9F+

The airline I worked for operated them in the desert southwest, where ambient temps routinely exceed 100°F. Given the short-hop, quick-turn nature of the flying we did, and the eye-watering current required to start a >2,000shp engine, we kept a close eye on those gauges.

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

185.27 KB |

| Viewed: |

9663 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Mar 21, 2019 5:05 am Post subject: Battery BMS failures? Posted: Thu Mar 21, 2019 5:05 am Post subject: Battery BMS failures? |

|

|

| Quote: | So the agile BMS watches temperatures

and strives to limit those effects

on the cells irrespective of system

demands from the outside. |

Oh yeah, forgot to include charge balancing.

Unlike most battery chemistries, individual

cells in a series string of lithium may

become 'unbalanced'. This simply means that

one or more cells may 'top off' sooner than

the rest. If the charging continues until

all cells are topped off, there is risk

for over-charging the fast learners thus

insulting their sensibilities.

This is generally accomplished by placing

a load resistor across the faster cells

thus forcing more charge energy into the

slow cells until everyone is in lock-step . . .

consider a cell balancer to be the

ISO9000 of the lithium battery community.

Here's an article from Battery University

on the topic . . .

https://tinyurl.com/y3egekew

. . . yesterday's missive was intended to

illustrate that the term "BMS" is un-defined

in the consumer world and maybe not well

defined in the engineering world either. Unless you

have access to the designer's product performance

specification, it's wise to investigate

before you plunk down your beer money

for a battery upgrade. The full constellation

of products offered are NOT interchangeable

nor are they necessarily plug-n-play into

our legacy electrical systems.

In light of this fact, the phrase "BMS

failure" in any dark-n-stormy-night

story is not very informative unless

the narrator offers specific failure

analysis data . . . almost NEVER a

component of such stories.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Mar 21, 2019 7:37 am Post subject: Battery BMS failures? Posted: Thu Mar 21, 2019 7:37 am Post subject: Battery BMS failures? |

|

|

| Quote: |

Indeed, the deHavilland DHC-8-202 that I flew in a previous life was fitted with battery temperature gauges on the overhead panel (just below the left fire t-handle in the linked image).

https://bitly.com/2uj9V9F+

The airline I worked for operated them in the desert southwest, where ambient temps routinely exceed 100°F. Given the short-hop, quick-turn nature of the flying we did, and the eye-watering current required to start a >2,000shp engine, we kept a close eye on those gauges.

Eric |

Did you ever have occasion to take

a hot battery off line?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 261

|

Posted: Thu Mar 21, 2019 8:52 am Post subject: Battery BMS failures? Posted: Thu Mar 21, 2019 8:52 am Post subject: Battery BMS failures? |

|

|

| Quote: | On Mar 21, 2019, at 08:36, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com> wrote:

Did you ever have occasion to take a hot battery off line?

|

Just once, but not in flight. After flying three Phoenix-Yuma-Phoenix round trips on an especially brutal July day, we exceeded limits and couldnât start up for the fourth scheduled Yuma turn. I canât say that either of us was particularly bothered by the forced break!

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

yellowduckduo(at)gmail.co

Guest

|

Posted: Thu Mar 21, 2019 9:30 am Post subject: Battery BMS failures? Posted: Thu Mar 21, 2019 9:30 am Post subject: Battery BMS failures? |

|

|

On 21/03/2019 11:36 AM, Robert L. Nuckolls, III wrote:

| Quote: | >

> Indeed, the deHavilland DHC-8-202 that I flew in a previous life was

> fitted with battery temperature gauges on the overhead panel (just

> below the left fire t-handle in the linked image).

>

> https://bitly.com/2uj9V9F <https://bitly.com/2uj9V9F>+

>

> The airline I worked for operated them in the desert southwest, where

> ambient temps routinely exceed 100°F. Given the short-hop,

> quick-turn nature of the flying we did, and the eye-watering current

> required to start a >2,000shp engine, we kept a close eye on those

> gauges.

>

> Eric

Did you ever have occasion to take

a hot battery off line?

Bob . . .

An aircraft of that size and vintage may have had a battery charger that

|

monitored temperature and could limit charging current??

It seems like the Lithium "BMS" strategies are moving in that direction.

Limiting the alternator size as per Earth-X recommendations is a small

step in that direction which I applaud. Even with VRLA batteries I

tossed my 100+ amp alternator in favor of a 40 amp unit.

Ken

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 261

|

Posted: Thu Mar 21, 2019 3:58 pm Post subject: Battery BMS failures? Posted: Thu Mar 21, 2019 3:58 pm Post subject: Battery BMS failures? |

|

|

| Quote: | On Mar 21, 2019, at 10:28, C&K <yellowduckduo(at)gmail.com> wrote:

An aircraft of that size and vintage may have had a battery charger that monitored temperature and could limit charging current??

|

Donât quote me on this (itâs been awhile...) but as I recall, the temperature monitoring was separate from the charger. I think the chargerâs only âdata inputsâ were weight-on-wheels and where its AC Power was coming from (external or engine-driven generator).

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jimkale(at)roadrunner.com

Guest

|

Posted: Thu Mar 21, 2019 10:13 pm Post subject: Battery BMS failures? Posted: Thu Mar 21, 2019 10:13 pm Post subject: Battery BMS failures? |

|

|

I was a 28 year Army Active Duty helicopter pilot. In the mid 70's I had a

Nicad helicopter battery completely melt down. Just molton liquid in the

steel box container. Fortunately the hydrogen did not ignite. We smelled

it and then noticed a terrifically high charge rate. We landed the CH-47

helicopter and we opened the battery box to find the mess. A few years

later the Army put a warning in the manual to land if you smelled the rotten

egg smell and get out of the helicopter get away from it and not to touch

the battery. Finally in the 90s the manufacturer put a battery charger in

the circuit which limited the charge current to about 10 amps. It

prevented thermal runaway charging which could happen with the battery just

tied to the main bus and a 200 amp generator attached to the bus.

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Mar 22, 2019 5:53 am Post subject: Battery BMS failures? Posted: Fri Mar 22, 2019 5:53 am Post subject: Battery BMS failures? |

|

|

| Quote: | An aircraft of that size and vintage may have had a battery charger that monitored temperature and could limit charging current??

It seems like the Lithium "BMS" strategies are moving in that direction. |

Don't think so. The 'charger' was not much

different than what we have in our airplanes:

An engine driven power source regulated to

idealized charging levels for the battery.

Some airplanes had two engine driven sources

like starter generators. These would parallel

for delivering up to 800A. The larger

aircraft would also have a auxiliary power

unit good for perhaps 200-300 amps that could

be operated in parallel with ships generators.

None of the generator controls were fitted with

any way to monitor either battery temperature or

current.

| Quote: | | Limiting the alternator size as per Earth-X recommendations is a small step in that direction which I applaud. Even with VRLA batteries I tossed my 100+ amp alternator in favor of a 40 amp unit. |

But suppose your running loads call for more

current? Heated seats maybe? Electric cockpit

heat a la LongEz? A B400 has electric

de=ice on the tail feathers . . . lots

of amps needed there.

Virtually every rechargeable battery's maintenance

instructions call for constant-current/constant-voltage

recharge profiles. I.e. limit current into the

battery to some friendly level until the desired

bus-voltage set point is reached whereupon you

change to constant voltage operation.

All it takes is a current sensor on the battery

feeder to monitor the battery's recharge

current and adjust bus voltage to maintain

fast recharge at the recommended current

until the battery is topped off whereupon

the controller reverts to constant voltage.

Not difficult to do for any combination of

battery and engine driven power sources.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Mar 22, 2019 6:01 am Post subject: Battery BMS failures? Posted: Fri Mar 22, 2019 6:01 am Post subject: Battery BMS failures? |

|

|

| Quote: | | Don't quote me on this (it's been awhile...) but as I recall, the temperature monitoring was separate from the charger. I think the charger's only data inputsâ were weight-on-wheels and where its AC Power was coming from (external or engine-driven generator). |

If the aircraft had 3-phase alternators

and separate starters, then DC power was

derived from transformer/rectifiers to

run DC systems and recharge batteries.

These aircraft were generally large enough

to carry an APU which was used to start

engines thus reducing demands on the battery.

These systems could easily include features

for battery management.

But for twin-jets up through ships like

the Hawker 800 series, batteries were

connected to a bus powered by generators

with a LOT of output capability. Any

necessary monitoring of battery temperatures

was a simple thermometer gage with warning

and danger lights.

It was up to crew to notice and then

take an overheated battery off line until

it cooled.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 261

|

Posted: Fri Mar 22, 2019 7:42 am Post subject: Battery BMS failures? Posted: Fri Mar 22, 2019 7:42 am Post subject: Battery BMS failures? |

|

|

| Quote: | On Mar 22, 2019, at 07:00, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com> wrote:

If the aircraft had 3-phase alternators and separate starters, then DC power was derived from transformer/rectifiers to run DC systems and recharge batteries.

These aircraft were generally large enough to carry an APU which was used to start engines thus reducing demands on the battery.

|

The Dash-8s of this vintage had Pratt & Whitney PW123Ds (2,150 shp/side) with starter/generators. There were also AC generators (thatâs what they called them!) and TRUs. It was a complex electrical system, to put it mildly.

The planes were available with APUs, but the airline chose not to install them. The reasons for that remained a mystery to most of us who flew them, as the plane was an overpowered beast that had no trouble hauling a full cabin and bulked-out cargo bins. The extra couple hundred pounds would have made zero difference in performance, but would have improved interior comfort and reduced battery demands enormously. As it was, all of our engine starts were battery powered for #2, then tie the DC buses to start #1 assisted by the #2 generator.

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|